In this post we are going to describe letter bending machine training in Brisbane, QLD. JDA08 letter bending machine from Jiading machinery, China used in this project.

Similar projects done with PDMach about letter tech can be viewed here and here

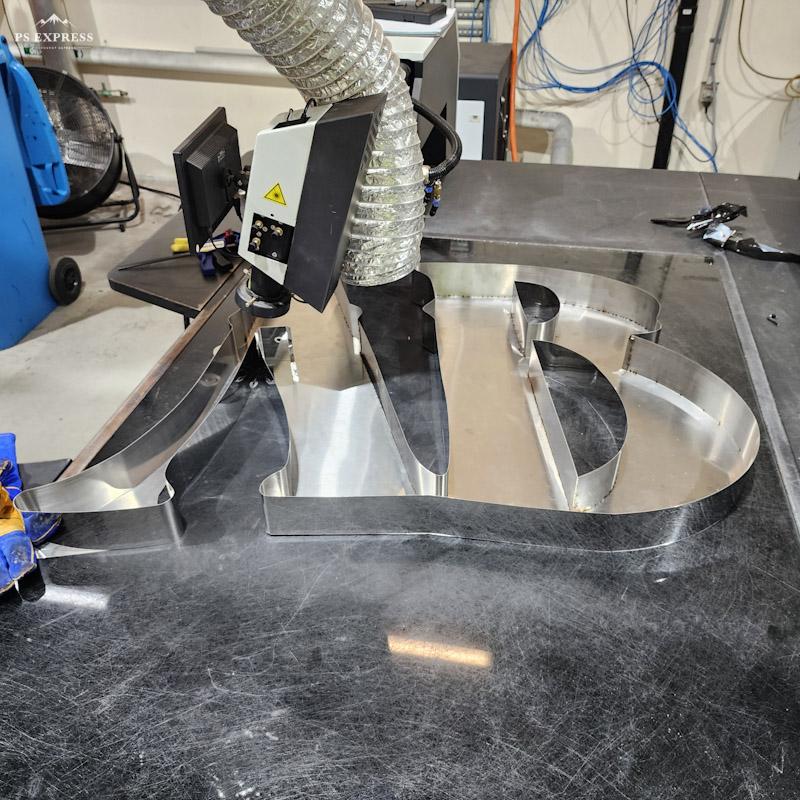

Letter bending machine laser welding showed at the last section.

Letter bending machine training in QLD

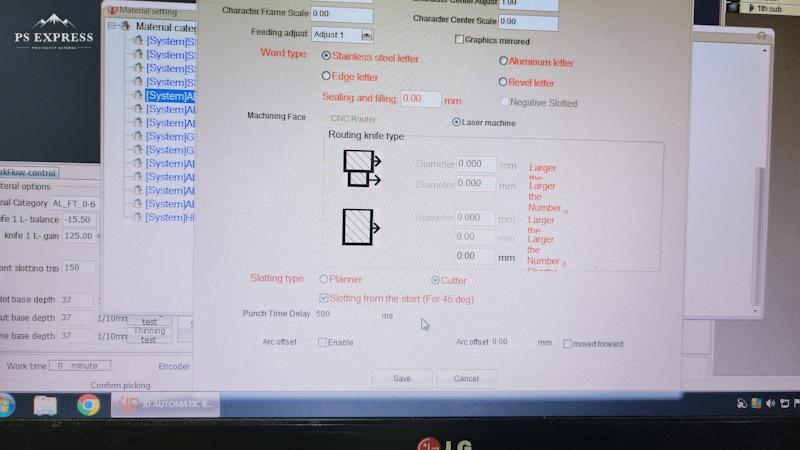

We started training on this channel letter bending machine with general settings, firstly knife bending and knife gain. This procedure done with knife calibration file in “Parameters” menu. For right knife bending the outer picking should be selected and for left knife bending the inner picking. After that, knife gain test has to be done, too. For each section, totally four tests need to be done.

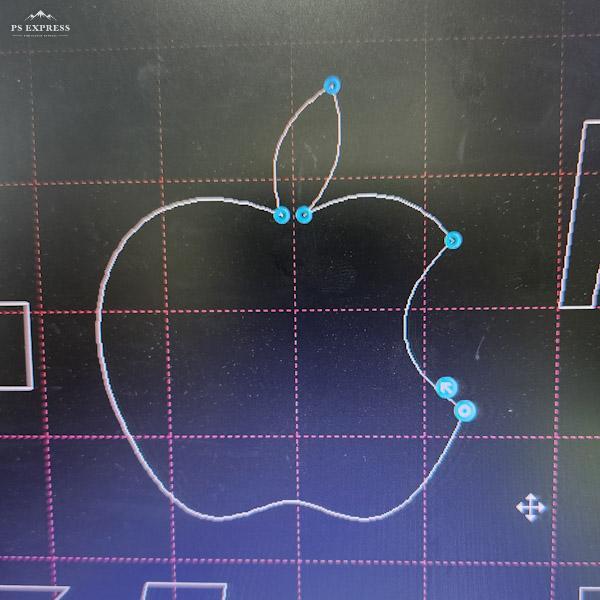

Letter bending machine training for an Apple sign

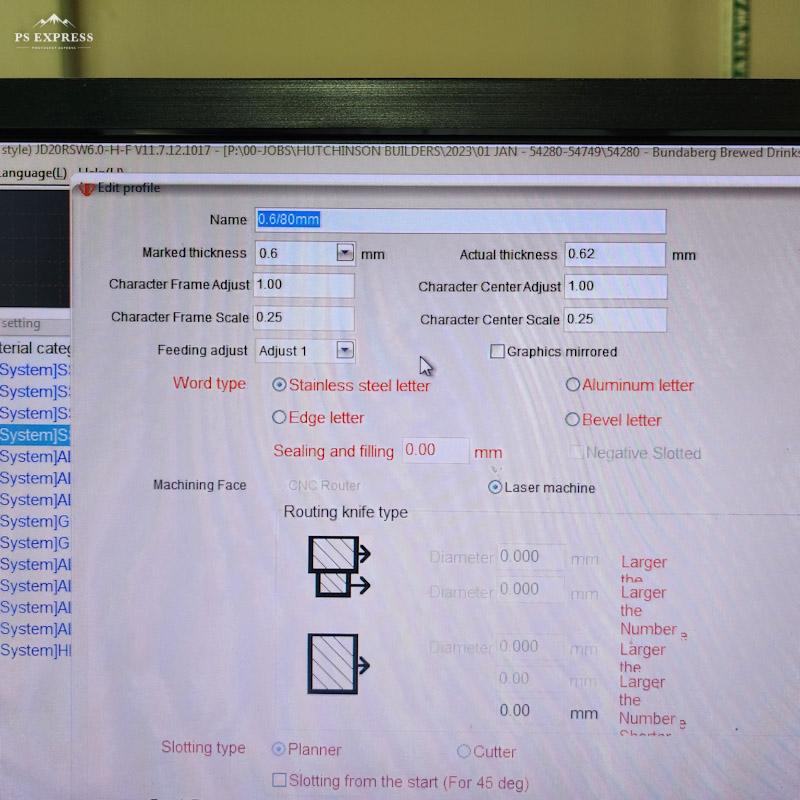

One of the issues we had with aluminium sections was not slotting at sharp edges, like Apple sign, and bending very sharp at that points.

This even caused machine stop during the bending process because of bending knife engagement.

We ended up selecting stainless steel in material setting for this sections! I mean in aluminium category we did bending and gain test for mentioned section, just in material setting ticked stainless steel and that fixed calculation issue.

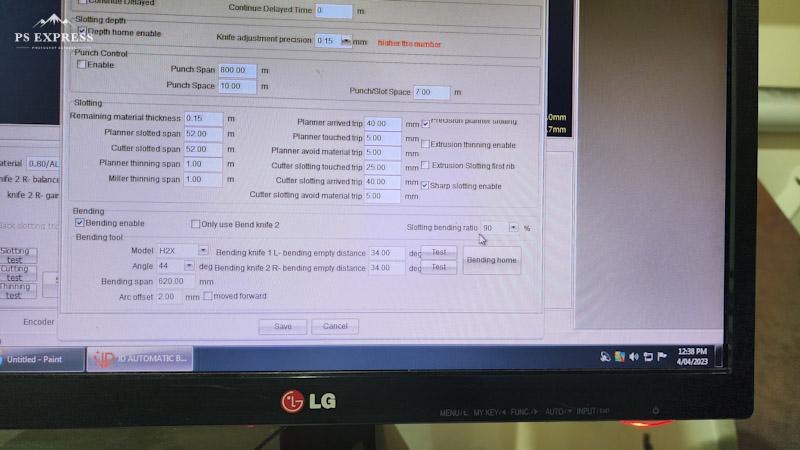

Slotting bending ratio

We have an option in parameters setting named “Slotting bending ratio”, if you leave it at 0 it won’t bend straight slots while doing the channel and just sends the material out straight.

If you like to have the nearly close output like your file you can put 80% or 90% in “Slotting bending ratio”.

If you like to have your first section slotted and like 45 degrees, you can tick “Slotting from the start (For 45 deg)”. This would add around 20mm to your letter’s beginning.

Letter bending machine training for calibration

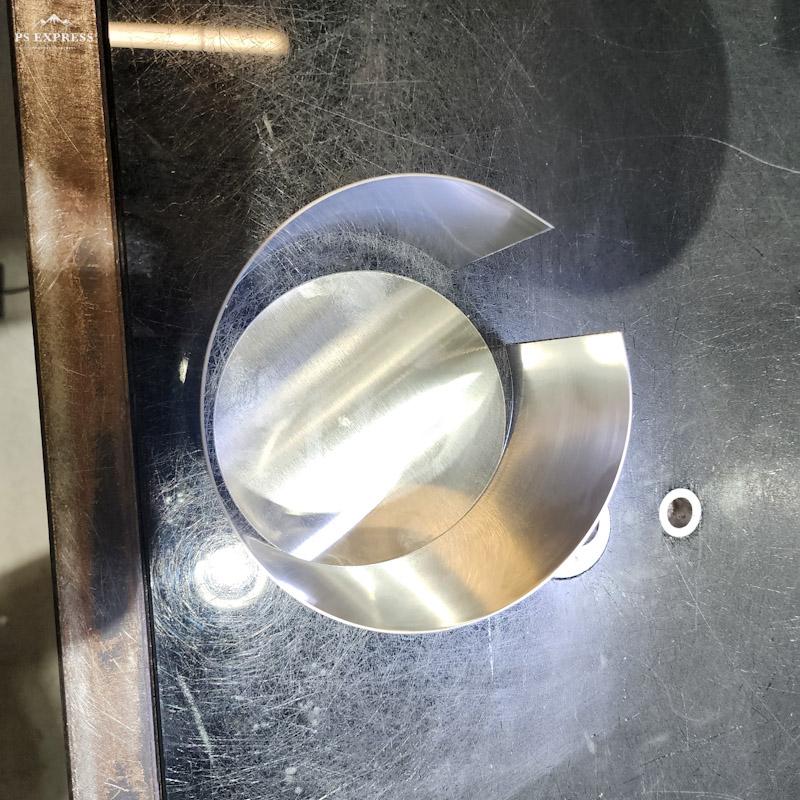

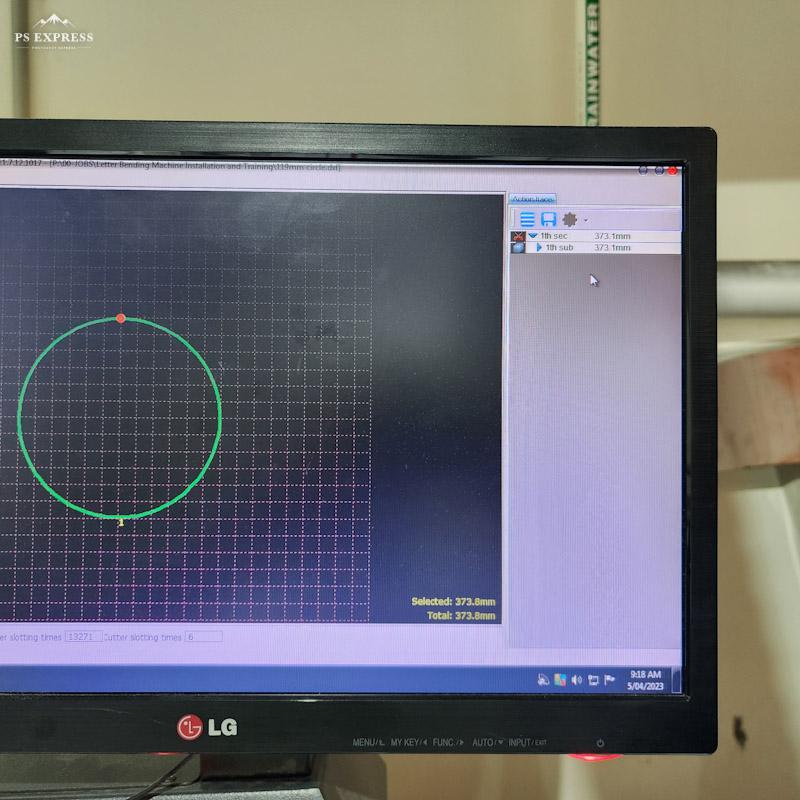

After doing bending calibration tests and length calibration test, one of the best suggestions is to process a round piece to compare length and make sure base and returns matching.

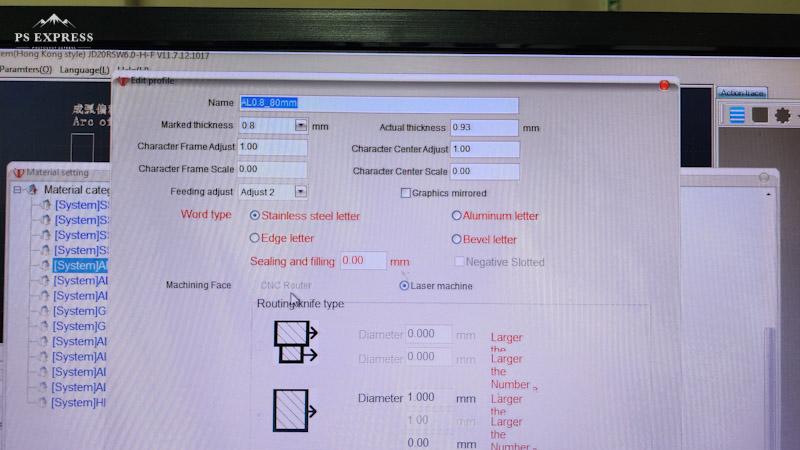

Character frame scale

After inner or outer selection the software would show the processing length. We got an option to scale the processed length in material setting. In our experience in Brisbane we used 0.25 scale for stainless steel and -0.25 for aluminium, both 80mm returns.

Letter welding in this Letter bending machine training

For welding these letters, multifunctional letter bending machine laser or heavy duty soldering with at least 50% tin, can be used.

No comment