Some projects on SCM woodworking CNCs have been explained in this page.

In the following project, the machine had 2 independent Y axis servo motors and home switches.

After an incident, the home point changed for one side, and machine was unable to finish the calibration process.

The connection between the bridge and Y axis motor connection has opened and by taking advantage of the special screw set for squareness adjustment, the bridge brought back to normal.

After the repair, machine has been tested for normal work and tool changing.

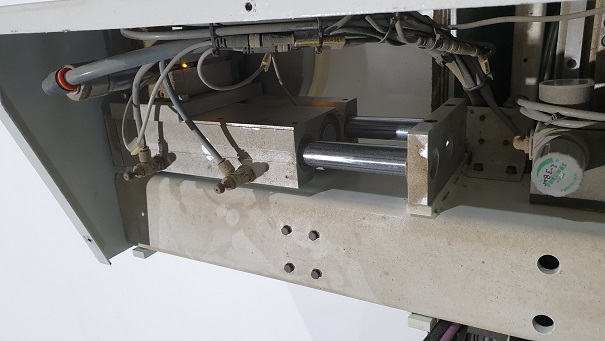

Another project was about loading cell repair on SCM Pratix S

The sensor set and machine working checked in action to see the actual reason for the alarm. The electric diagram used for sensor progressive action and the problem found on misalignment of the loading section body. After loading some new batch and hitting the forklift, the loading section had moved and that caused the issue. After pushing back the body, the problem solved.

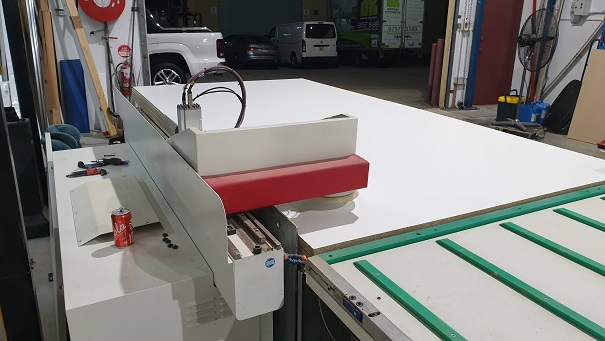

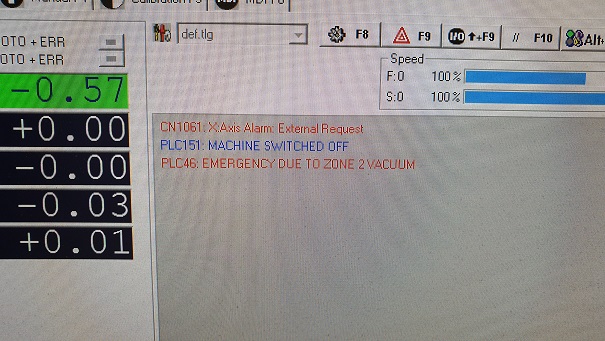

The other day, we focused on vacuum suction issue in two major sheet sizes, on that SCM Pratix S.

We have two normal sheets sizes, here in australia. 1200*2400mm and 1800*3600mm. In this machine we had 2 zones, consist of two vacuum valve sets. The idea is to have vacuum everywhere on the table for a full sheet, 1836, and to have the small sheet size area on 1224 sheets.

This machine have O ring and vacuum plugs for vacuum section management.

The rubber O rings and vacuum plugs have been used in a way to plug the outer area when the small sheet is in use, and suck the whole table for full sheets.

This machine has been used for signage and custom jobs, too.

SCM Pratix فتوکل علی الله