About Us

Welcome

A Few Words About Us

This page is about Precision Diamond Machinery, with more than 20 years of experience in service, design and manufacturing of industrial machinery.

Ali, the former machinery designer and manufacturer, would help you find perfect solutions for current and future changing demands.

Ali started his business journey when was very young. After year 5, every year had been doing school holiday jobs in metal machining shops and machinery manufacturing.

In year 12, enrolled a course for computer programming.

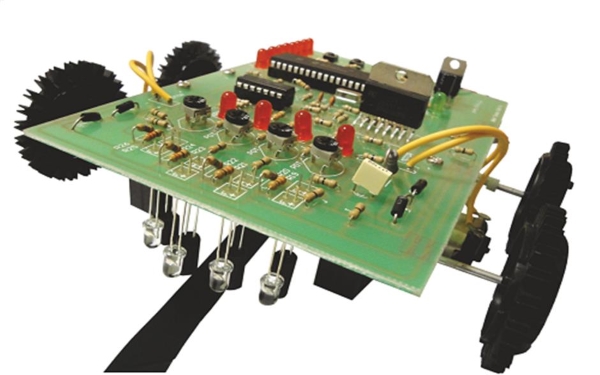

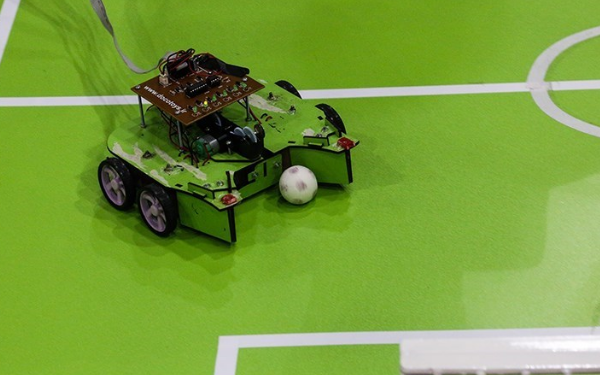

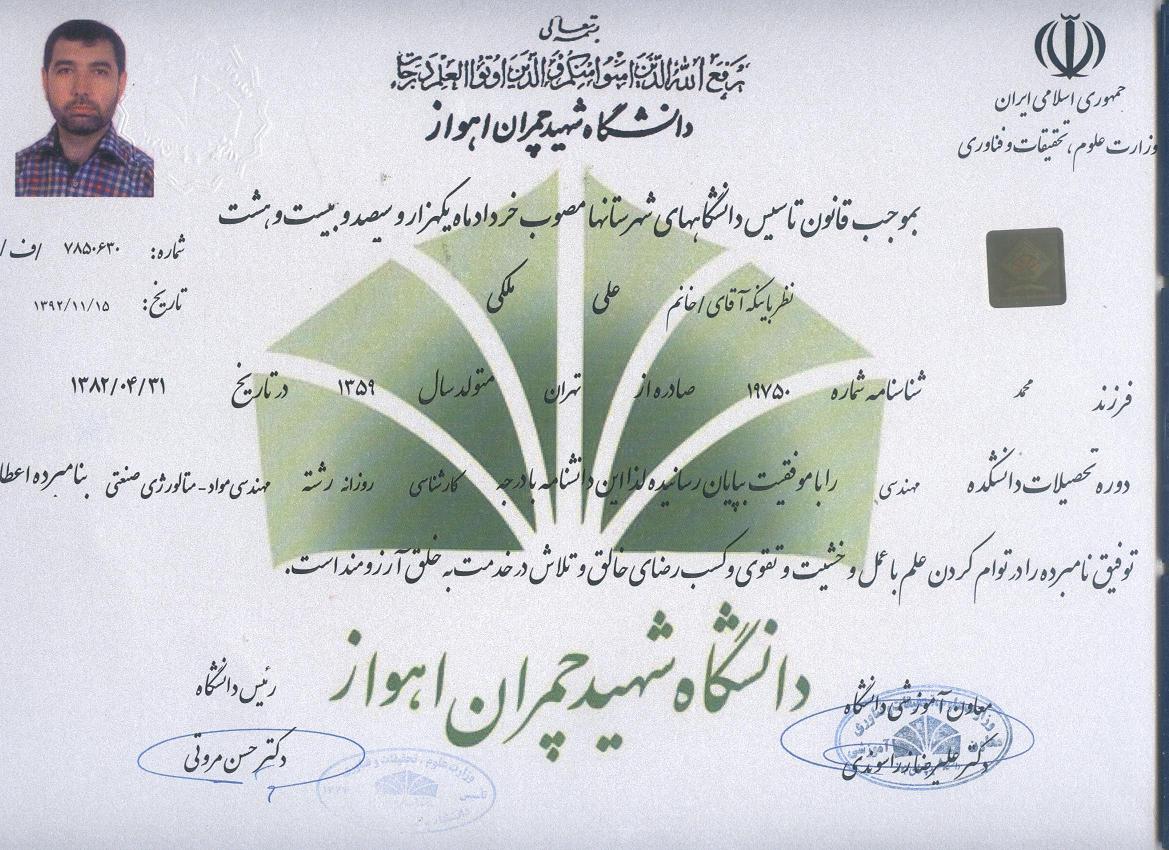

Meanwhile studying the engineering in Shahid Chamran of Ahwaz, he was the faculty robotic team leader for national competitions.

And at the same time did part time apprenticeship in metal working and machinery manufacturing workshop.

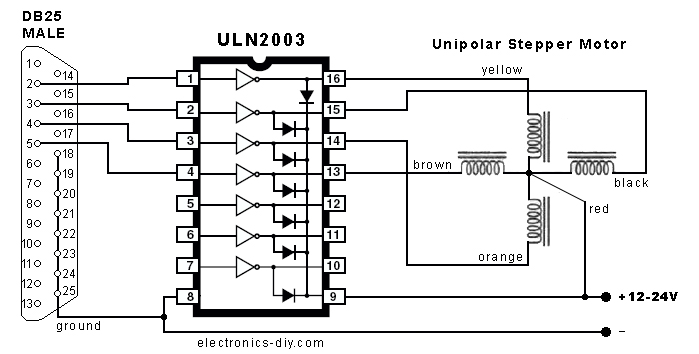

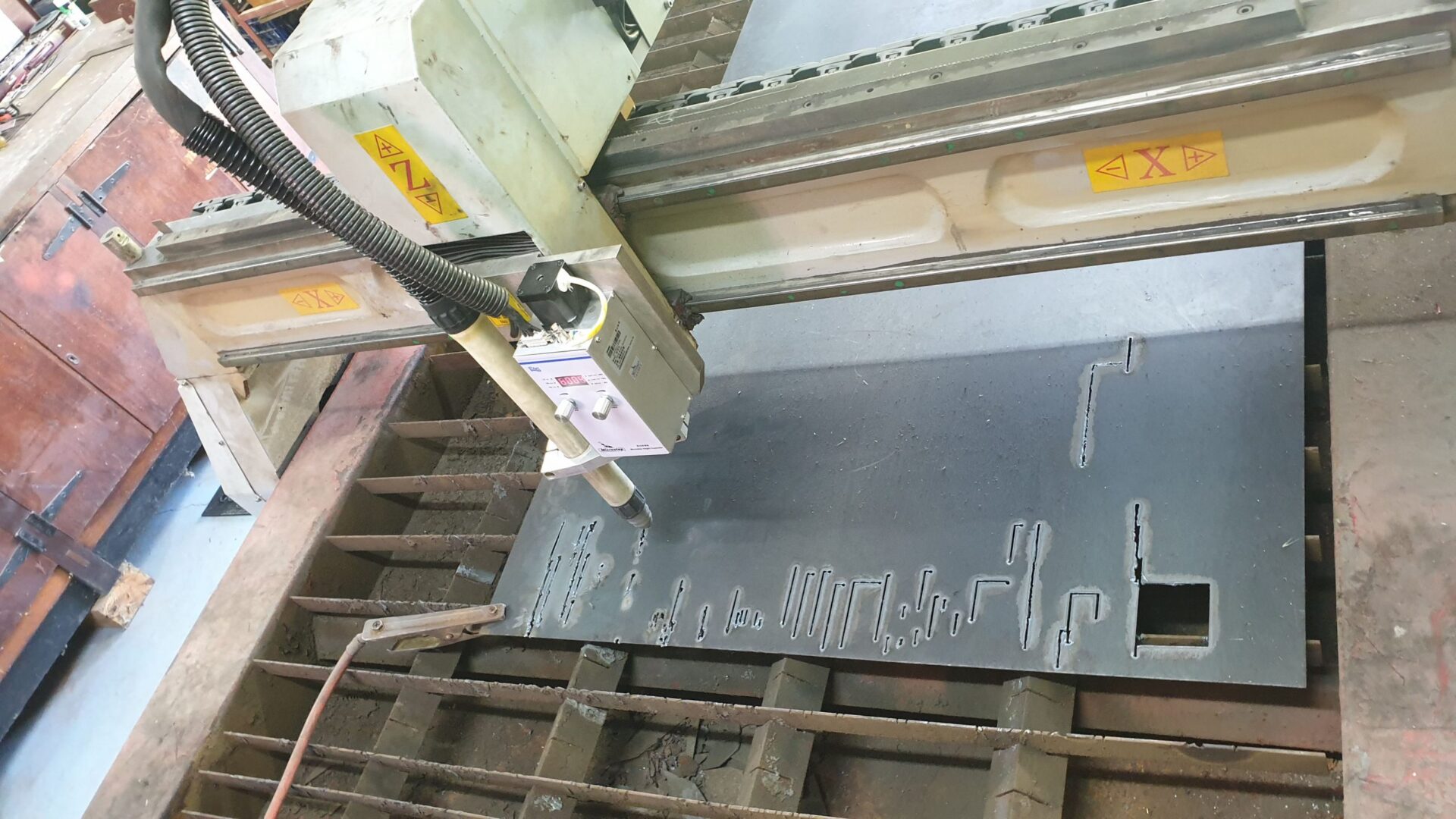

After university, started a business, making CNC machines, from the scratch. At that time you needed to use a PC with D25 parallel port to command your stepper motor interface.

About the first 3 axis CNC controller, a laptop with D25 port, Mach3 and an in-house made ULN2003 circuit had been used.

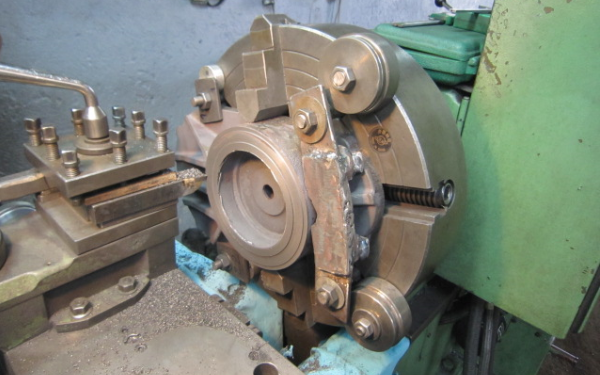

After that, for many years focused on machinery manufacturing processes and factory management.

Different processes like lathe machining, milling, welding, cutting and painting has been done and managed.

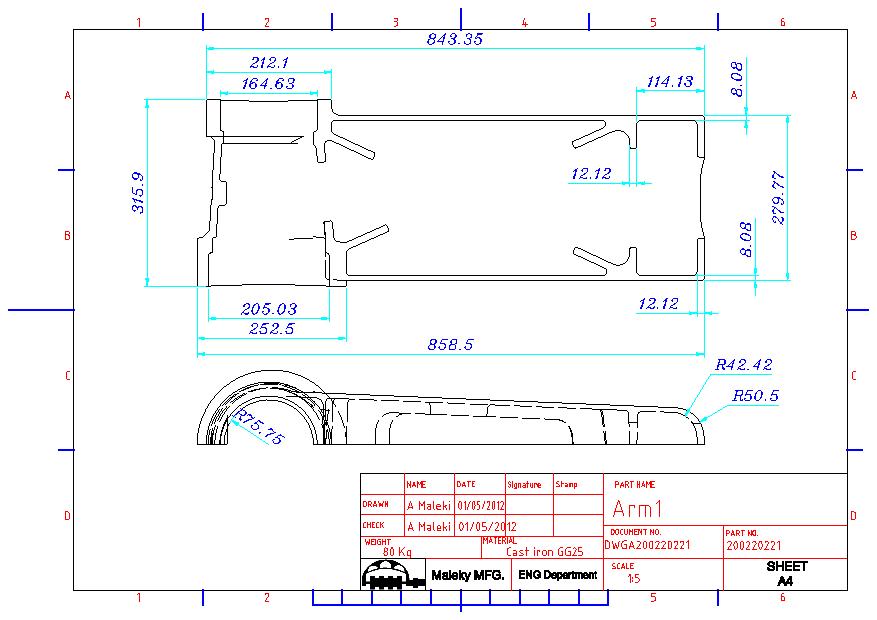

In many cases needed to modify machinery designs with solid modelling softwares like Mechanical desktop, CATIA, Solidworks or make brand new designs.

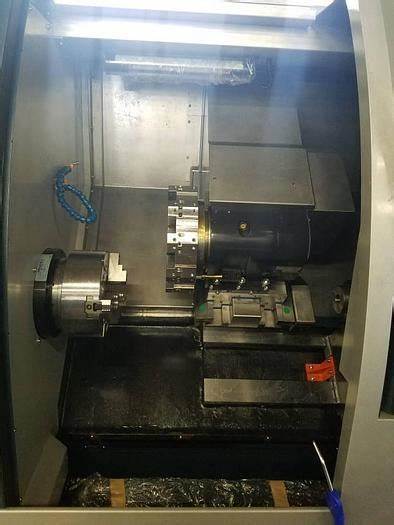

Meanwhile, used and taught CNC lathe machine because of increasing demand for machinery.

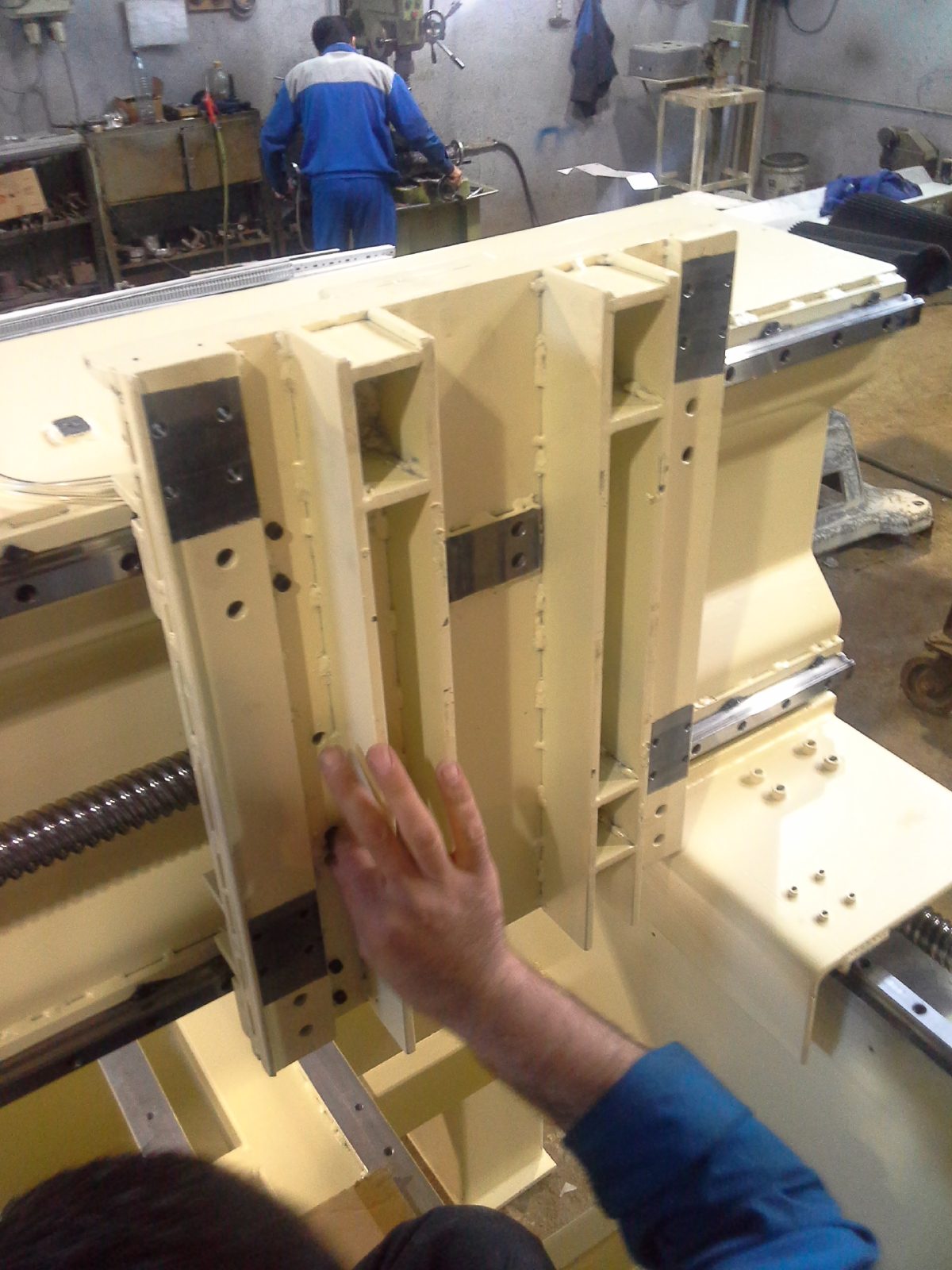

In machinery manufacturing, you need to make too many foundry patterns for sand casting of iron and aluminum products. That’s why spent many years researching the best design techniques and had taken the advantage of CNC milling machine to make big or small casting patterns.

Meanwhile, started to learn more about factory management. First human resource, then payroll processes, then accounting knowledge and softwares, then project management and time planning techniques, according to PMBOK guidelines.

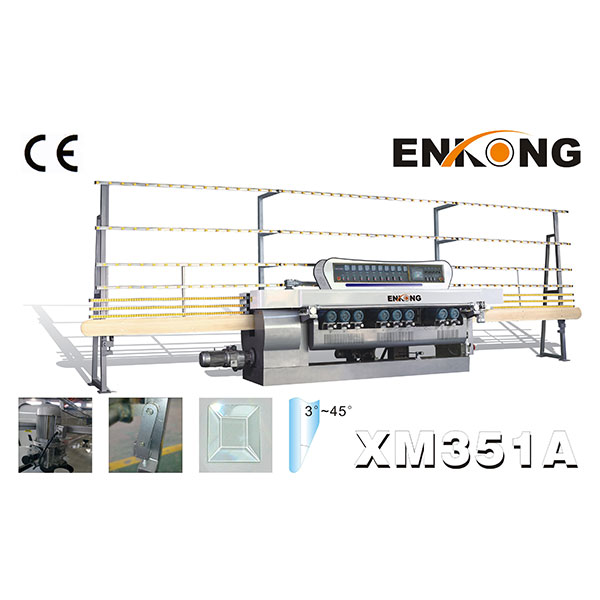

Around 2007, started to design brand new machinery in glass preprocessing. First developed the formula for controlling the devices. Then mechanical and finite element techniques had been used to optimise the structure. Then the structure had been made and exclusive PLC program developed to control the process.

After that, again focused in CNC machine design for many years. Special CNC engraving and edge polishing machine had been made for glass sink manufacturing.

Sales, import, installation and support of industrial glass pre-processing machinery from 2008

Then continued the process to make glass engraving CNC, because of development in local controller industry. Then after that made a huge, 3000*1600mm special designed glass engraving CNC.

About migrating to Australia, I had a business for glass machinery service, at the same time have been working as an INTERMAC AUSTRALIA associate for CNC machinery field service.

Now engaged with maintenance management at a big glass factory in Sydney and supporting CNC machinery in Australia market.

Certificates & licenses

Concept!

Engineering knowledge helps to find the problems quicker! That’s our competitive advantage.

With the experience in manufacturing process, it’s possible to understand customers better and give them better long term solutions.

Our business is engaged with different industries, including but not limited to “Signage, Metal cutting, Wood, Stone and Glass”. This wide range of machinery increased our capabilities to give you best options, in terms of service and support.