Welcome

A Few Words About Us

More than 18 years of experience in service, design and manufacturing of industrial machinery

Ali, the former machinery designer and manufacturer, would help you find perfect solutions for current and future changing demands.

This is why

You Should Choose Us

Precision, Expertise, and Efficiency

In the Modern context of advanced manufacturing, Computer Numerical Control (CNC) machines stand as indispensable tools, serving as the driving force behind precision, heightened productivity, and the embrace of automation. These complex machines are the workhorses behind industries ranging from aerospace to automotive and medical device manufacturing. Nevertheless, similar to any mechanical equipment, CNC machines are prone to wear and tear and can experience unexpected malfunctions. When these precision instruments falter, CNC repair becomes an essential service, ensuring the seamless continuation of production. In this article, we explore the world of CNC repair, its critical importance, key considerations, and why entrusting this task to experts is paramount.

The Critical Role of CNC Repair

CNC machines are at the heart of modern manufacturing, offering unparalleled precision, repeatability, and speed. These machines are programmed to perform intricate tasks with micron-level accuracy, and even the slightest deviation from their specifications can result in costly downtime, reduced product quality, and a decline in profitability.

The need for CNC repair arises due to various reasons

Regular maintenance is crucial to keep CNC machines in optimal working condition. Wear and tear, contamination, and calibration drift must be addressed promptly to prevent larger issues.

Like any machinery, CNC machines can experience unforeseen breakdowns due to mechanical failures, electrical issues, or software glitches. Rapid repair is essential to minimize production disruption

As technology advances, manufacturers often opt to upgrade their CNC machines or retrofit them with new components to enhance performance. These modifications require expert handling.

Over time, certain components of CNC machines, such as bearings, spindles, or controllers, may wear out and need replacement.

Key Considerations for CNC Repair

Effective CNC repair necessitates a methodical approach and a profound comprehension of the associated technology. Here are some crucial considerations:

The first step in CNC repair is accurate diagnostics. This entails pinpointing the underlying cause of the problem, whether it’s mechanical, electrical, or software-related issues. Skilled technicians use a combination of tools, including diagnostic software and hands-on inspection, to pinpoint the problem.

The process of repairing CNC machines frequently requires the replacement of damaged or worn-out components. Having access to a reliable source of genuine spare parts is essential to ensure the longevity and performance of the repaired machine

Once the repair is completed, the CNC machine must undergo rigorous calibration and testing to ensure it meets its original specifications. This step is critical to maintain precision and repeatability.

To prevent future breakdowns, it’s essential to implement a preventive maintenance schedule. Regular inspections, cleaning, lubrication, and component checks can extend the lifespan of CNC machines and reduce the likelihood of unexpected failures

Prioritizing safety should remain top priority throughout the CNC repair process. Technicians must follow industry-standard safety procedures and ensure that the repaired machines are safe to operate.

Our Services

We provide CNC service and repair in Sydney metropolitan area. Our main services included mechanical, electrical, software and pneumatic repairs on CNC machines.

Plasma CNC

Another area of our service is CNC machine tool repair for metal working. CNC routers for aluminum, CNC milling machines, CNC lathe and CNC plasma, are example of the machines we service.

Oversized CNC router for cargo box fabrication

Another area of our service is CNC machine tool repair for metal working. CNC routers for aluminum, CNC milling machines, CNC lathe and CNC plasma, are example of the machines we service.

Biesse ARTECH edge bander

As part of our woodworking machinery service for our clients, we service and repair panel saw and edge banders.

CX-1390 Typical Chinese edge bander

As part of our woodworking machinery service for our clients, we service and repair panel saw and edge banders.

CNC router relocation, Marrickville NSW

CNC machines are widely used for signage. CNC router for making letters and signs and Co2 laser CNC are the most popular machine in this area. We offer on site services to support local businesses.

Co2 laser installation, Prospect NSW

CNC machines are widely used for signage. CNC router for making letters and signs and Co2 laser CNC are the most popular machine in this area. We offer on site services to support local businesses.

INTERMAC CNC MASTER 33

CNC repair for industrial glass processing machinery. CNC technology has been used widely in glass processing factories. Machines, like CNC polishing machines, CNC cutting tables, vertical work centres, INTERMAC Vertmax, CMS Vertical CNC and laminate lines. INTERMAC, Bottero, Hegla, CMS and Bavelloni are some of the brands in this industry.

INTERMAC GENIUS CT CNC Cutting table

CNC repair for industrial glass processing machinery. CNC technology has been used widely in glass processing factories. Machines, like CNC polishing machines, CNC cutting tables, vertical work centres, INTERMAC Vertmax, CMS Vertical CNC and laminate lines. INTERMAC, Bottero, Hegla, CMS and Bavelloni are some of the brands in this industry.

DENVER CNC

Other service we offer is for stone processing CNC machines. Mainly for countertops manufacturing factories, including bridge saw, CNC polish machine and waterjet cutting machine. Machineries including INTERMAC, Breton, Donatoni, EMMEDUE, GMM and YongDa Waterjet.

EMMEDUE Bridge saw

Other service we offer is for stone processing CNC machines. Mainly for countertops manufacturing factories, including bridge saw, CNC polish machine and waterjet cutting machine. Machineries including INTERMAC, Breton, Donatoni, EMMEDUE, GMM and YongDa Waterjet.

BIESSE Rover S

We service woodworking CNC machines for cabinet joineries, shop fit outs and decoration suppliers. The major brands are BIESSE, SCM, Masterwood, ANDERSEN and RHINO. We supply mechanical, electrical and pneumatic service for woodworking CNCs.

Rhino Woodworking CNC

We service woodworking CNC machines for cabinet joineries, shop fit outs and decoration suppliers. The major brands are BIESSE, SCM, Masterwood, ANDERSEN and RHINO. We supply mechanical, electrical and pneumatic service for woodworking CNCs.

Homag vantage 33L repair in Sydney

We service woodworking CNC machines for cabinet joineries, shop fit outs and decoration suppliers. The major brands are BIESSE, SCM, Masterwood, ANDERSEN and RHINO. We supply mechanical, electrical and pneumatic service for woodworking CNCs.

Plasma CNC

Another area of our service is CNC machine tool repair for metal working. CNC routers for aluminum, CNC milling machines, CNC lathe and CNC plasma, are example of the machines we service.

Oversized CNC router for cargo box fabrication

Another area of our service is CNC machine tool repair for metal working. CNC routers for aluminum, CNC milling machines, CNC lathe and CNC plasma, are example of the machines we service.

Biesse ARTECH edge bander

As part of our woodworking machinery service for our clients, we service and repair panel saw and edge banders.

CX-1390 Typical Chinese edge bander

As part of our woodworking machinery service for our clients, we service and repair panel saw and edge banders.

CNC router relocation, Marrickville NSW

CNC machines are widely used for signage. CNC router for making letters and signs and Co2 laser CNC are the most popular machine in this area. We offer on site services to support local businesses.

Co2 laser installation, Prospect NSW

CNC machines are widely used for signage. CNC router for making letters and signs and Co2 laser CNC are the most popular machine in this area. We offer on site services to support local businesses.

HSD spindle repair

We repair CNC machinery spindle. Mainly for glass processing, stone CNC, woodworking CNC and CNC routers.

Services including bearing replacement, sensors diagnostic and repair, encoder check and rewinding.

5 axis spindle for INTERMAC Master 45

We repair CNC machinery spindle. Mainly for glass processing, stone CNC, woodworking CNC and CNC routers.

Services including bearing replacement, sensors diagnostic and repair, encoder check and rewinding.

ATC spindle with tool magazine and drill block on Andersen CNC

CNC repair is a critical service that ensures the continued functionality of precision manufacturing equipment. As CNC machines become increasingly complex and integral to modern production, the need for expert repair services has never been greater. Entrusting the repair of CNC machines to professionals with the knowledge, experience, and access to genuine parts is an investment in the reliability and efficiency of manufacturing operations. In an era where precision and productivity are paramount, mastering the art of CNC repair is a strategic imperative for manufacturers across industries

HSD spindle kit replacement for BIESSE Rover

CNC repair is a critical service that ensures the continued functionality of precision manufacturing equipment. As CNC machines become increasingly complex and integral to modern production, the need for expert repair services has never been greater. Entrusting the repair of CNC machines to professionals with the knowledge, experience, and access to genuine parts is an investment in the reliability and efficiency of manufacturing operations. In an era where precision and productivity are paramount, mastering the art of CNC repair is a strategic imperative for manufacturers across industries

HSD ES369L spindle shaft

CNC repair is a critical service that ensures the continued functionality of precision manufacturing equipment. As CNC machines become increasingly complex and integral to modern production, the need for expert repair services has never been greater. Entrusting the repair of CNC machines to professionals with the knowledge, experience, and access to genuine parts is an investment in the reliability and efficiency of manufacturing operations. In an era where precision and productivity are paramount, mastering the art of CNC repair is a strategic imperative for manufacturers across industries

laser welding demonstration

We supply and install laser welding machine and channel letter bending machine.

We also offer service, repair and machine support for signage industry.

Channel letter bending machine

We supply and install laser welding machine and channel letter bending machine.

We also offer service, repair and machine support for signage industry.

Aluminum laser welding

We supply and install laser welding machine and channel letter bending machine.

We also offer service, repair and machine support for signage industry.

EXCELLENTTrustindex verifies that the original source of the review is Google. I truly want to thank Precision Diamond Machinery Pty Ltd for their outstanding service. It was honestly one of the best experiences I’ve had with a technical company. From the very first contact, their communication was respectful, friendly, and professional. You can tell right away that you’re dealing with a team that genuinely cares and takes pride in their work. They are highly skilled and knowledgeable, and they took the time to explain everything clearly and patiently. You can really feel that they know what they’re doing and have a deep understanding of their field. What stood out to me the most was their commitment to quality and customer satisfaction. Not only did they complete the job with precision and professionalism, but they also followed up afterward to make sure I was happy with the results. If you’re looking for a reliable, experienced, and approachable team, I 100% recommend Precision Diamond Machinery Pty Ltd. It was a pleasure working with them.Trustindex verifies that the original source of the review is Google. As someone new to CNC controlled machines and the proud owner of a (new to me) 3 axis CNC router I was in desperate need of support to assist me with fault finding the my machine’s controller as some training on how to configure and use it. This was made all the more difficult living in Darwin, Northern Territory. After some google searching I found Ali who has been my life saver. Ali is extremely knowledgeable with CNC machine control, very very patient and and a great trainer. I was so lucky to find Ali from Precision Diamond Machinery and am 110% confident in recommending him to anyone. All of the support provided was via What’s App video calls which made it very easy for both of us to understand and progress Thanks Ali for your excellent support and service Rob Bonney Darwin, Northern TerritoryTrustindex verifies that the original source of the review is Google. Fantastic service, fast response and well mannered. Was an absolute pleasure to do business with Precision diamond machinery, excellent quality built machinery, nothing is a problemTrustindex verifies that the original source of the review is Google. I would recommend you to everyone, good workTrustindex verifies that the original source of the review is Google. Ali arrived on time and very promptly to look at my imported CNC machine. 3 other technicians had previously looked at my CNC and while they said it was going well, I knew deep down it was not functioning as it should. Ali cleaned and serviced my machine and gave me some pointers as to how to get the most out of my CNC. Importantly, he discovered that my machine was only running at 3000rpm while it was capable of running at 18000 rpm. He did of course adjust it. This explains why I had so many broken tools. My program was running at 18000 rpm but the machine wasn't. Thank you AliTrustindex verifies that the original source of the review is Google. I cannot recommend Precision Diamond Machinery enough. Ali has been nothing but helpful in all areas. He has come out within days of needing a fix of our machine, being so efficient and fixing problem in a timely manner. Without a doubt, he has helped me understand my machine so much better and offered maintenance & assistance in an industry that so desperately needs it.Trustindex verifies that the original source of the review is Google. Outstanding and professional service. Thank you and see you next time.Trustindex verifies that the original source of the review is Google. Professional technician with great skills hard to find these days. You found the problem in my CNC Router machine in a very short time. I would recommend Ali to anyone who has a problem with their CNC machine. Steve CEO Drop TruckTrustindex verifies that the original source of the review is Google. Ali helped us installing and setting up the 2nd hand laser we purchased. We didn't know how to operate it, he gave us instructions, serviced it and even helped us finding a software to make it all happen. Ali also replied to further questions we had without delay. Would call upon his services any day.

Recent projects

Wheel repair CNC

Introduction In this post calibration and setup of a WRM28H wheel repair CNC machine described. The manufacturer page can be … Read More

letter bending machine calibration

In this post I am going to describe channel letter bending machine calibration in Melbourne. Similar projects done with PDMach … Read More

spindle repair

About Biesse Rover Plast B In this post we are going to show you HSD ES369L spindle repair. This project … Read More

letter bending and welding machines

Introduction This post is about letter bending and welding machines supply and install in Sydney. XQL-SB180 Channel letter bending machine … Read More

Edge bander repair

The Essential Role of Edge Bander Repair in Woodworking Woodworking is an art form and an industry where precision and … Read More

Laser power meter

HLP-200B A laser power meter is a handheld measuring device for effective Co2 laser beam power measurement. Some more information … Read More

Best Seller Products

-

General service

$150.00 Add to cart -

Stone saw blade

$250.00 – $450.00 Select options This product has multiple variants. The options may be chosen on the product page -

Nesting CNC

$65,000.00 Add to cart -

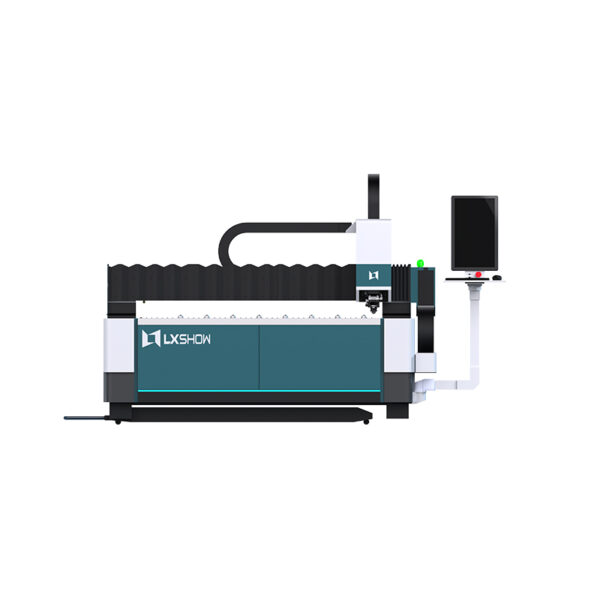

Fiber laser CNC

$54,000.00 Add to cart -

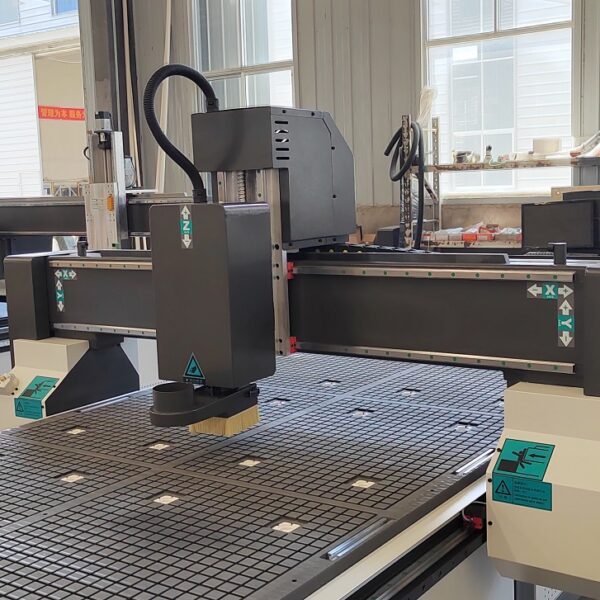

CNC Router 1325

$14,000.00 Add to cart