In this post I’m going to describe INTERMAC Master table shaving process.

After any machine relocation, even brand new, table rectification is needed to guarantee the required accuracy of these machines. Sometimes this process used for old residue removal, too.

Also, it’s recommended to rectify suction cups after table.

For this process 80mm face cutter with long sleeve is recommended.

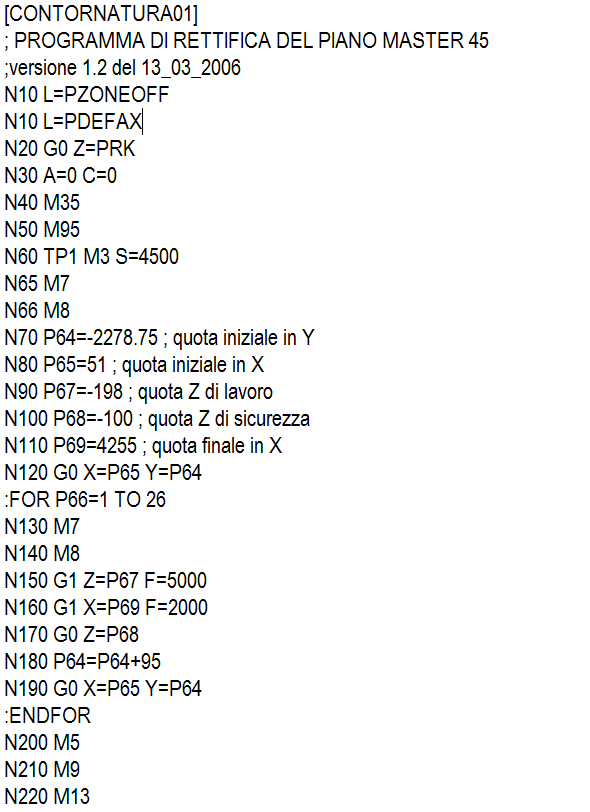

There is a standard file named “RETTIFICA_MASTER.CNI” in iso/COLLAUDO on machine’s computer. Tool height measurement is crucial and for shaving each machine has its own X and Y sizes. This program is taking advantage of loops to cover all table area.

It’s popular for many other CNC machine brands in stone and glass polishing industry.

Even for stone bridge saw, operator every once in a while, shaves table with a thick disk cutter.

In Biesse or other brands of wood working CNCs also skimming is needed. Like stone bridge saw, wood working CNC needs to be skimmed every once in a while. For wood CNCs commonly a spoil board used to avoid machine table be worn out.

No comment