In this post I am going to describe channel letter bending machine calibration in Melbourne.

Similar projects done with PDMach can be viewed here and here

letter bending machine calibration notes

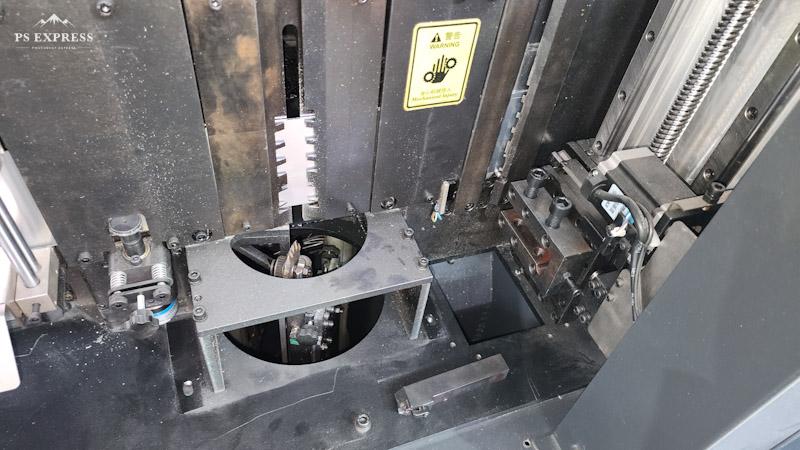

That machine was a VAM-S6 Plus letter bending machine from Varisigns company, China. It had a planner for stainless steel and milling cutter for plain aluminium and aluminium edge letters. It took advantage of a swing milling cutter which was doing rear cutting, too.

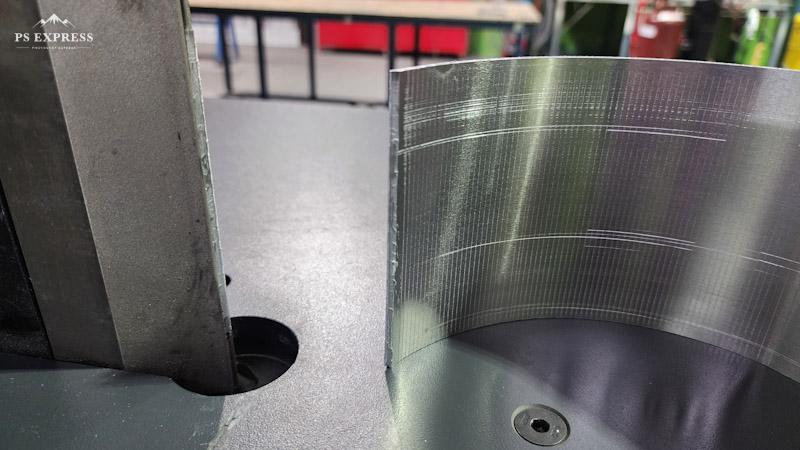

There is an obvious difference between planner and cutter for aluminium processing. The finished cutting surface of aluminium is rough with a planner, but a cutter with a multi tip would result in a much better result.

As a result, always try to use a cutter for aluminium profiles and edge letters.

User purpose

The main idea was to make edge letters with this machine. The edge letters raw material comes in 6 meter rolls, to be used with 3mm acrylic on top and 10mm base.

This way would result in cheaper 3D letters for customers, with eliminating welding and post processing.

letter bending machine calibration results

With this edge letters and taking advantage of a simple Co2 CNC machine, it’s possible to make small to medium 3D letters with gluing parts together.

letter bending machine calibration secret

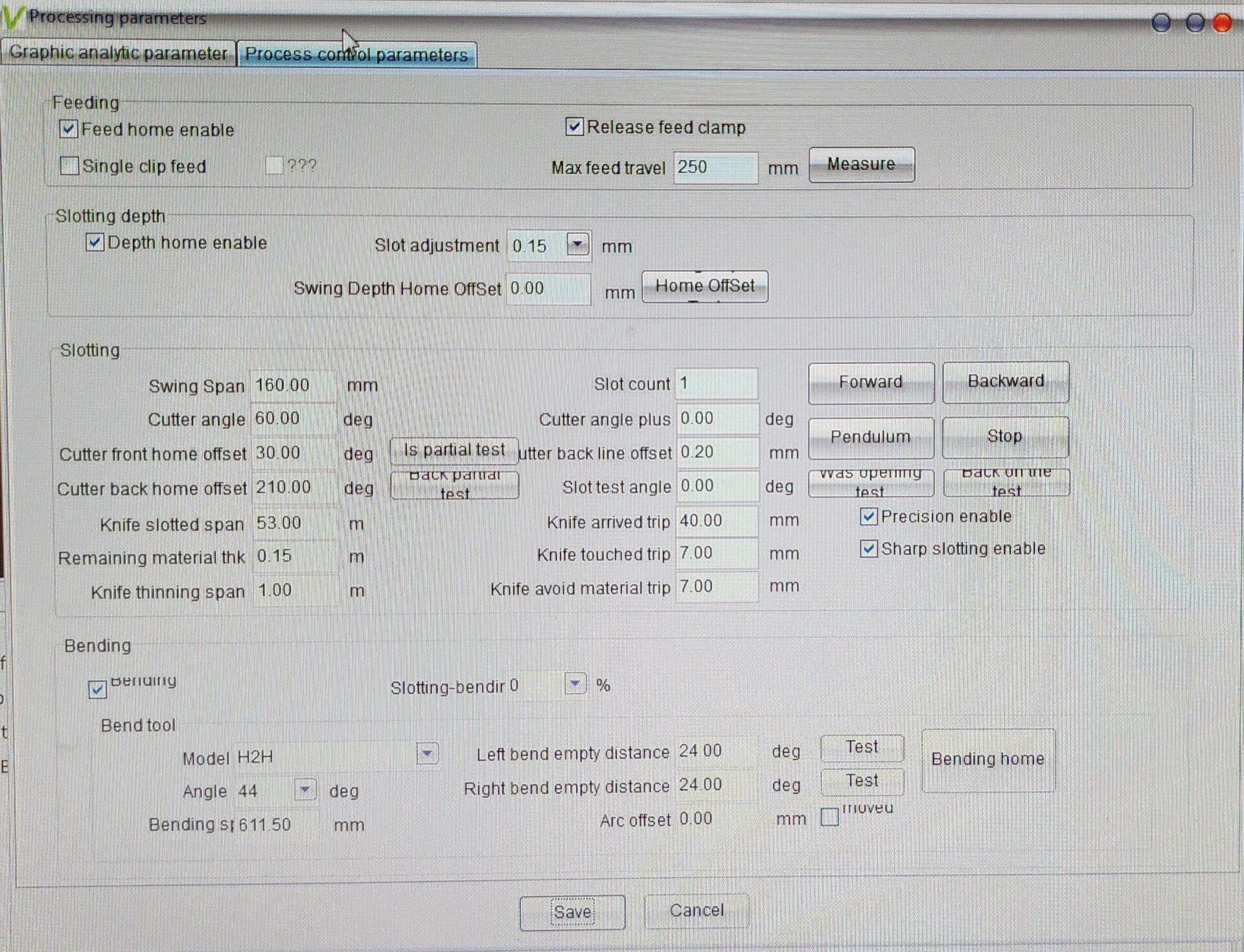

One of the important settings was “cutter front home offset”. In the beginning it was around 5 degree, then the machine was not able to make square corners, because of the negative limit. This parameter should be set at 30 degrees ideally. The only way to set it correctly is to lose the swing shaft connection and turn this shaft, to see the home switch in around 30 degrees. When you check the zero degree, swing cutter should straight towrds you.