introduction

Router CNC repair is one of our main services in Sydney.

CNC router is very powerful, affordable and useful machine in many signage shops and small custom fabrication facilities.

Some router CNC repair jobs are done over time on different CNC machines described below.

PDMach router CNC repair projects

Chinese CNC router installation in Prospect, Sydney

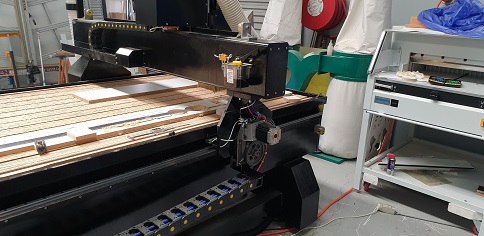

The job was about installing brand new Chinese unbranded CNC router.

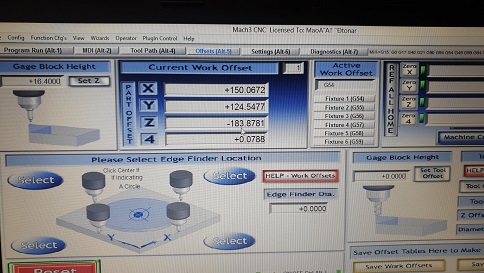

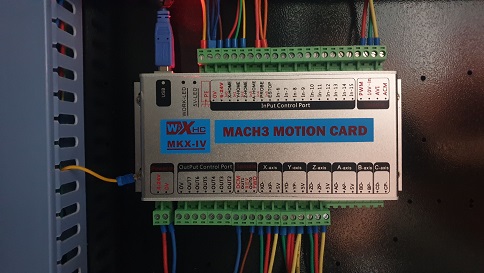

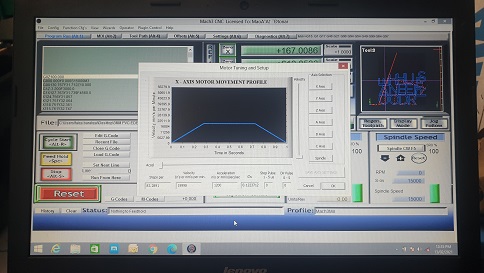

Mach3 is a PC based controller, which means using a PC to connect and control the CNC machine. It’s widely used and very convenient in many applications. We see too many Mach3 controllers in our router CNC repair projects in Australia.

The general levelling, parts connection, power connection and test done.

In general what needed for a CNC system to work is pulse or clock signal and direction for each axes. Means, two signal per axes is quite enough for it. These signals straight go to each axes drive, which would be stepper or servo drive. Servo is much better than stepper for a CNC router, because of closed loop on control circuit.

Power transmission

As per my experience, Chinese manufacturers are becoming more accurate with standard parts for their machines, which can be checked below.

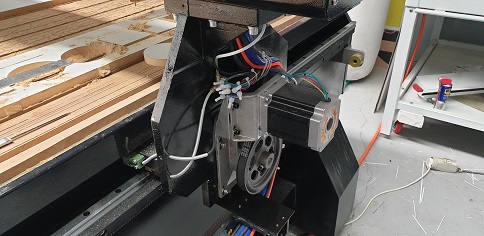

The stepper connection, timing belt and pulley mechanism is technically acceptable in this case. The only issue was wire not having any wiring number for future diagnostic and service.

Chinese router CNC repair with NK105 controller in Peakhurst, Sydney

This router CNC repair job was about calibrating the machine. It was not cutting correct size.

The reason for that can be deleting the controller’s memory or loosing the magnet over time in stepper motors.

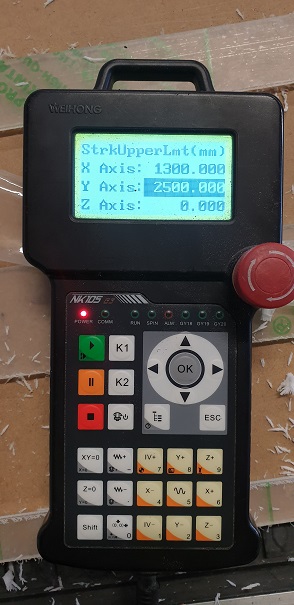

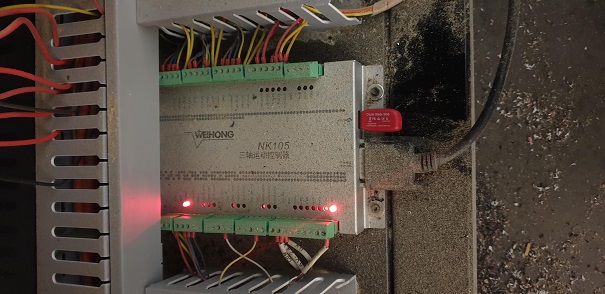

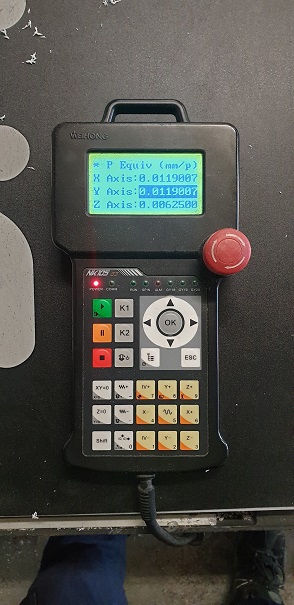

WEIHONG NK105 controller general shown below. The pulse and direction signals go to the stepper drive, limit switches inputs and inverter connection for spindle also connected.

The most important thing is this router CNC repair project was Pulse equivalent setting. This means adjusting the ration between each single pulse to smallest movement.

What I do usually, with the existing pulse equivalent setting, cut a sample piece, then compare the actual size and real cut size, then with calculating the ration needed to increase or decrease, calibrate the pulse equivalent.

Chinese CNC router installation in Buxton, NSW

The project was installation and training on a single tool Chinese CNC router

https://www.signstech.com/product_detail.php?ProId=190&CateId=18#.Yh8lftVBypo

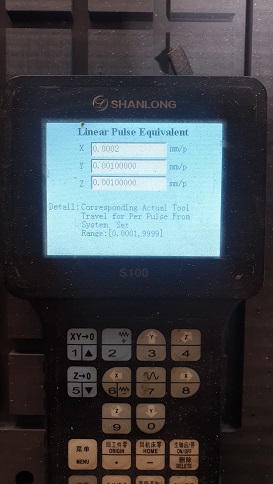

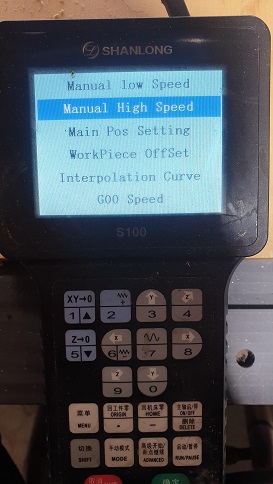

This machine was using SHANLONG controller.

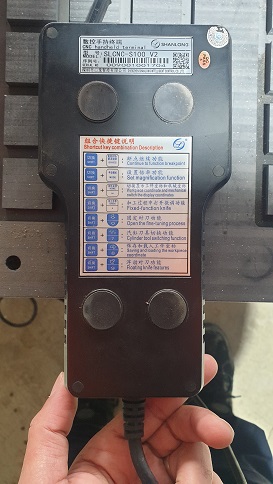

SHANLONG like WEIHONG NK105 is a DSP controller. DSP stands for digital signal processor. The main advantage for this kind of controllers is convenient and simplicity. This DSP controllers don’t need any PC to run the machine. Usually the G code generates in the office and can be transferred via USB stick or LAN connection. The main controller is connected via communication cable to the handheld.

More details about CNC controllers are here

Size calibration in router CNC repair

As mentioned above, almost always I had to check the size and make sure it’s ok.

In this case also I had to change the pulse equivalent ratio to make it right.

This days very good quality air cooled spindles can be found in China. The above spindle =, SIGNKEY branded is one good sample. Powerful and affordable spindle, enough for signage applications.

Vacuum zones

As shown above, this machine had 6 vacuum zones with manual control valves.MultiCAM CNC in Old Guildford, NSW

MultiCAM CNC in Old Guildford, NSW

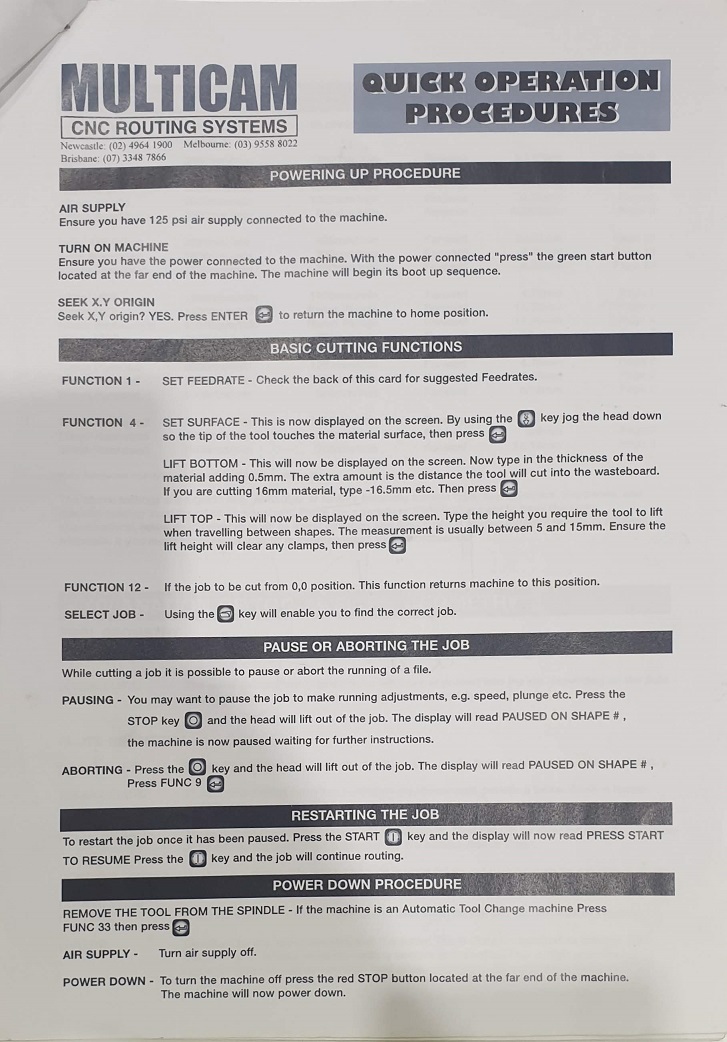

There was a job regarding operation and training of a MultiCAM series IIIS, Australian made CNC router with automatic tool changer.

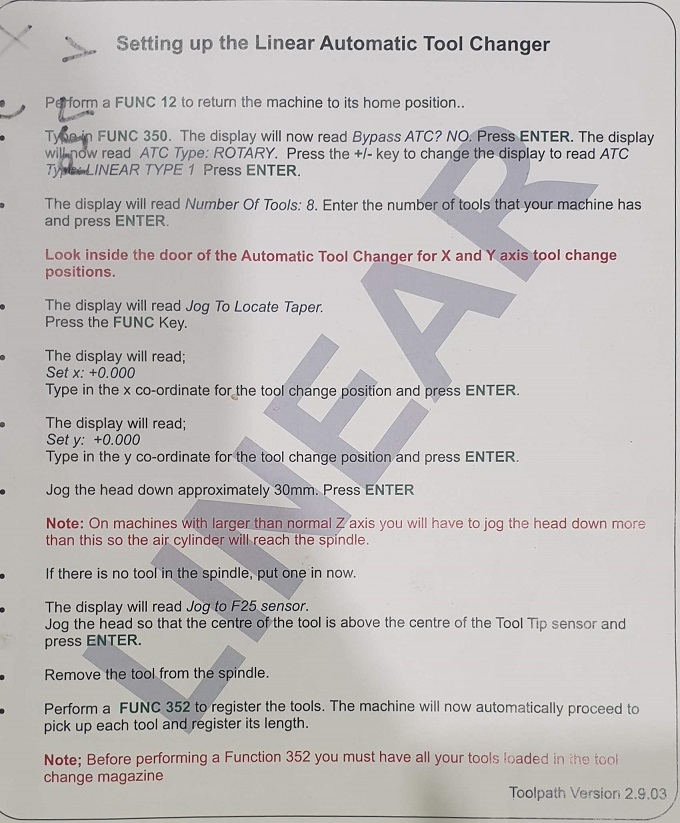

This machine takes the advantage of a linear tool changer and automatic tool height calibration, as shown below.

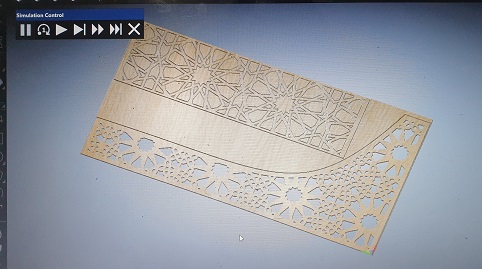

This machine is very convenient for signage shops and custom light duty machining facilities. 2D machining shown in below video.

MultiCAM is an Australian made product with simple functions and good support Australia wide. Part of the help file shown below.

Some parts of the quick operation manual which is very handy for the operator shown above.

The machine’s operator handheld can be used fixed on the machine, or remotely for better access and adjustment.

Another great feature on this machine is automatic tool calibration, as shown below.