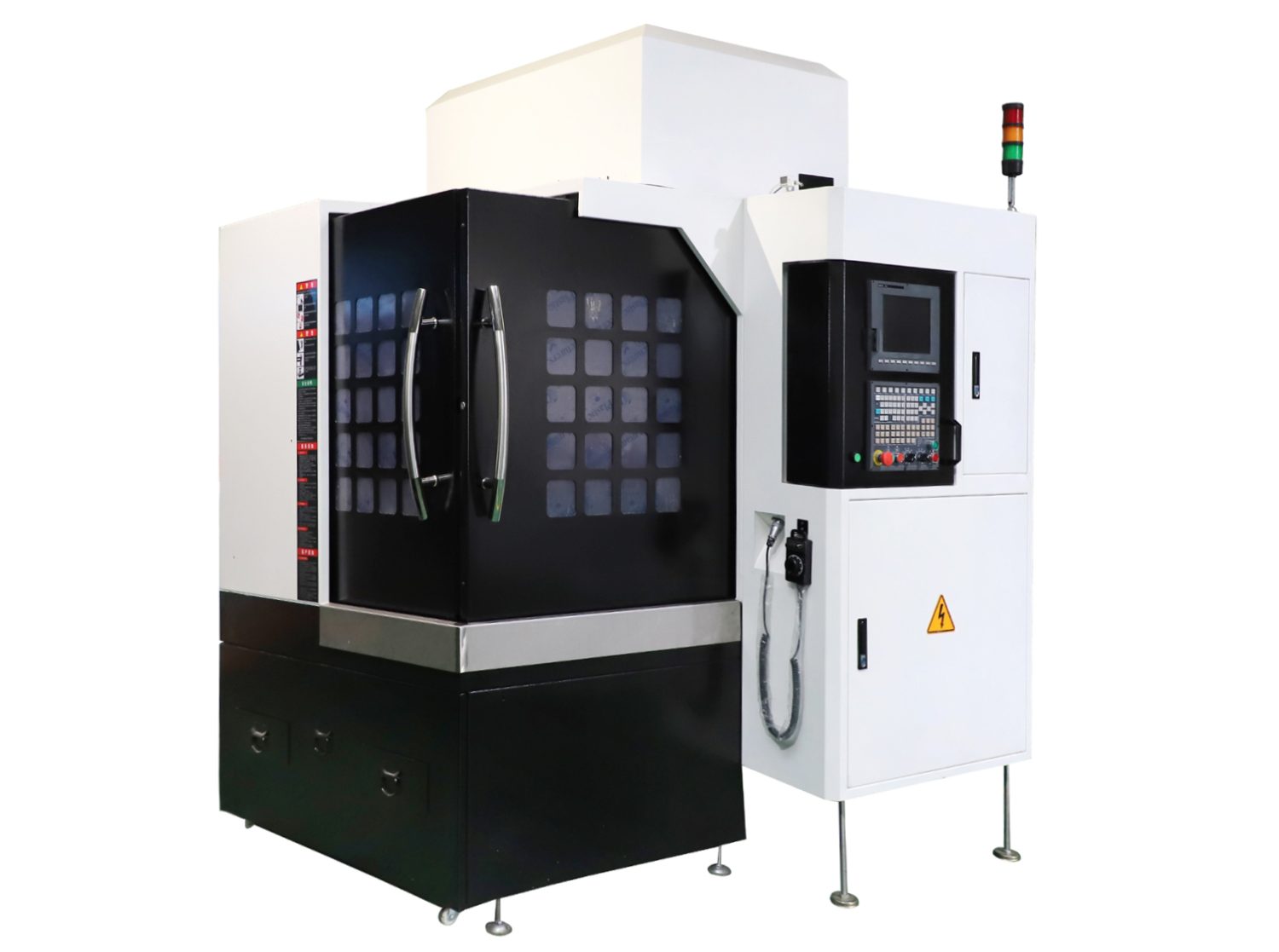

Mintech MD series CNC router specially designed for super shiny acrylic products, thanks to its ultimate rigid structure!

Working video

Mintech MD series MD6050

MD6050 Performance characteristics

The MD650 machining center adopts cast iron structure, table movement and beam fixed transmission mode. It adopts optimized design of gantry and beam and reliably cooperates with the worktable to form a frame structure with good rigidity and reliability. The finite element design calculation ensures the most Good strength and rigidity. In response to the high-quality processing requirements of acrylic, the mirror effect is directly achieved, the product quality is improved, the labor cost is reduced, and the production efficiency is improved.

MD650 CNC machining center, more than 15 years of industry application, industry-leading design, excellent performance and reliability.

Using high-quality components to use the machine tool can maintain high precision for a long time.

The machine components are FEM (Finite Element Analysis) and are uniquely designed to reduce vibration.

Safety Assurance

- The machine tool is designed according to the American AMT mechanical manufacturing standards.

– Electrical standards are designed using EMC electrical standards.

– All moving parts have safe and reliable protection.

– Operational status monitoring.

–X, Y and Z three-axis drive systems are equipped with a variety of safety protection controls, such as electrical control limits, software limits and mechanical limits to ensure the safety of machine work.

MD6050 Machine configuration list

| NO . | Project | Content | Regulation lattice Model | Preparation Note |

| 1 | Processing range | X-axis machining range | 600mm | |

| Y-axis machining range | 500mm | |||

| Z-axis machining range | 250mm | |||

| 2 | Machine parameter index | X, Y, Z axis motion positioning accuracy | Оmm | The above position parameters are referenced to the international ISO230-2 and are calibrated using a RENISHAW laser interferometer. Note (1) |

| X, Y, Z repeat positioning accuracy | 0.005mm | |||

| Maximum displacement speed | 10 m / min | |||

| Maximum processing speed | 6 m / min | |||

| Total machine weight | About 4500KG | |||

| Machine power supply requirements | AC380V/50HZ/3PH 30A | |||

| Machine tool gas supply requirements | 0.52MPa | |||

| 3 | Machine tool main purchase | cast iron | Precision Machining | Aging annealing heat treatment |

| 4 | Workbench | Cast iron workbench | T-slot 600mm × 500mm | |

| Workbench load | 400KG | |||

| 5 | CNC system | Taiwan’s new generation | 21MA bus (E80) | |

| 6 | Tool change system | Disc type BT30 | 12 knife position | |

| 7 | Tool setting system | Tool set | automatic | |

| 8 | Lubrication system | Fuel supply pump | automatic | Use No. 20 lubricant |

| 9 | motor | X, Y, Z axis | 850W AC servo | Yaskawa, Japan |

| 10 | Electric spindle | Spindle cooling | Oil cooler | |

| Spindle speed | 4000-24000RPM | |||

| Spindle power | 7.5 KW | |||

| Spindle taper | BT30 | |||

| Spindle dynamic balance level | G2.5 | |||

| Frequency converter | 7.5KW | Sifang or Delta | ||

| 11 | guide | X, Y, Z rail guide | Square rail (D30mm) | Taiwan Yintai |

| 12 | transmission | X, Y, Z axis drive | Ball screw (Ø32mm) | Taiwan silver |

| 12 | Arbor | BT30 | Pull studs and shank | 5 sets included |

| 13 | Tsui Tsui | ER32 | Ø3.175, Ø4, Ø6, Ø8, Ø10 | One each |

| Note(1): | Positioning accuracy detection method: The measurement data is sorted by mathematical statistics. That is, any number of positioning points (generally 5 to 15) are selected along a certain measurement axis parallel to the coordinate axis, and then multiple positioning (usually 5 to 13 times) is repeated for each positioning point. The locating point can be approached in one direction, or it can be approached from two directions, and then the measurement data is statistically processed to obtain an arithmetic mean value. Further, the average value deviation, the standard deviation, and the dispersion degree were determined. The dispersion represents the repeating positioning accuracy, which together with the average deviation constitutes the positioning accuracy, and the sum of the two is the maximum positioning deviation that can be achieved when positioning between any two points. |

Mintech T series, popular CNC routers, described here