In this page some recent projects on INTERMAC CNC Glass series described with photos.

Second hand INTERMAC CNC Glass installation

This project was installation of a second hand INTERMAC Master 33 in Braeside, VIC.

Skates have been used for easy machine moving.

All the mechanical and electrical parts managed and put in their spot in three days and machine started to be checked for proper function.

After every transport, even for a brand new machine, the table needs to be rectified by face milling tool.

In some cases, this process called shaving.

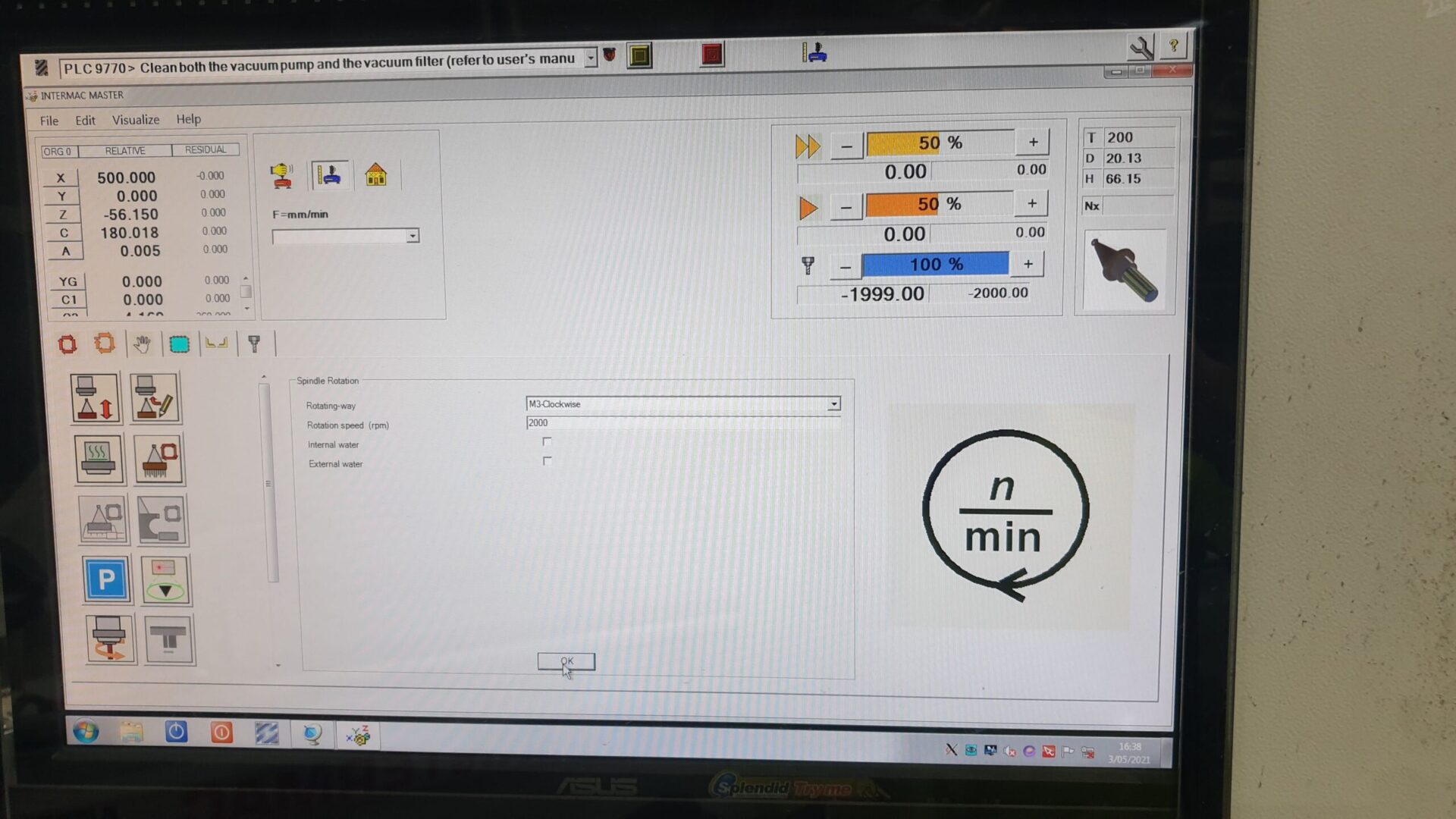

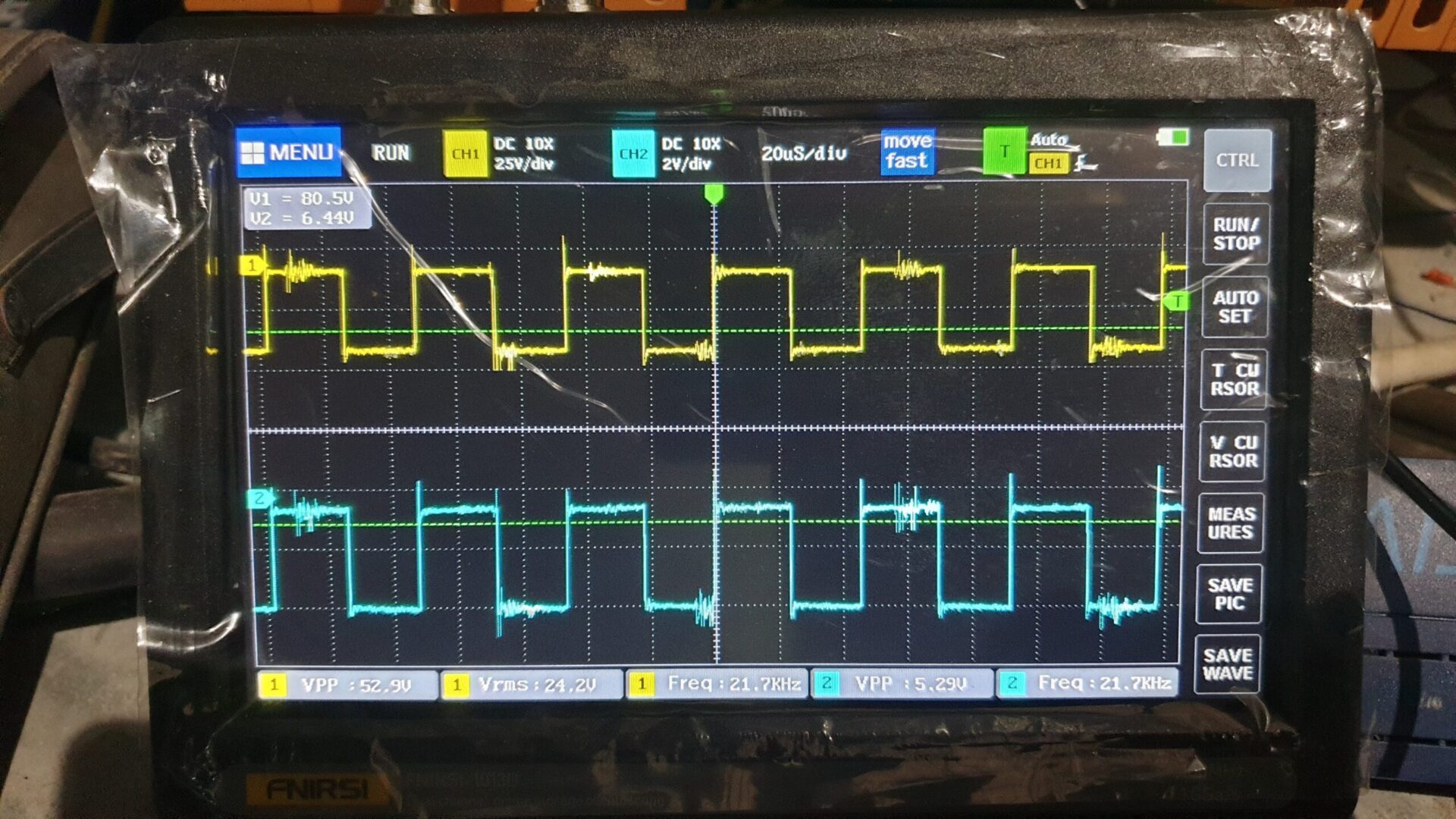

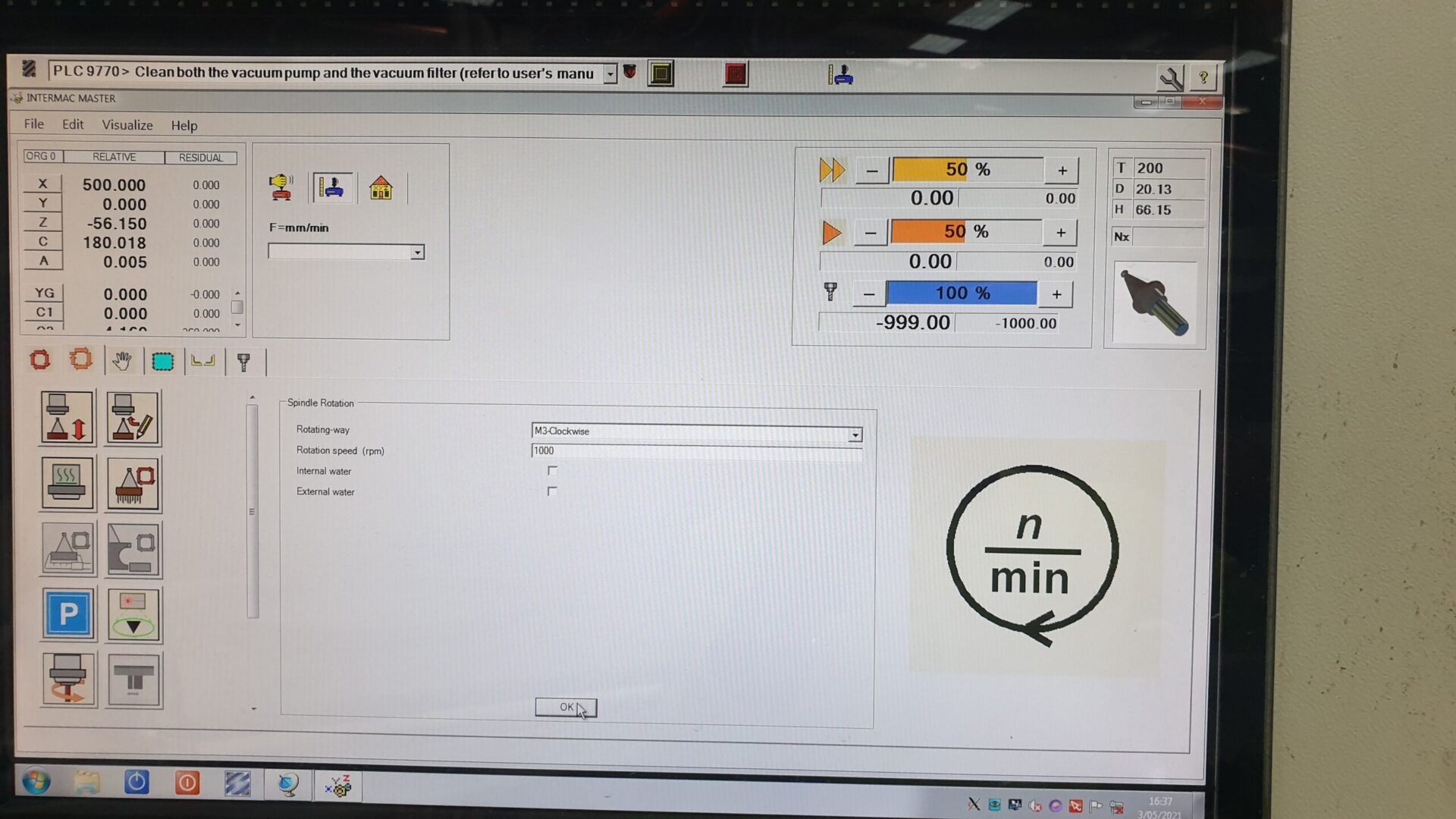

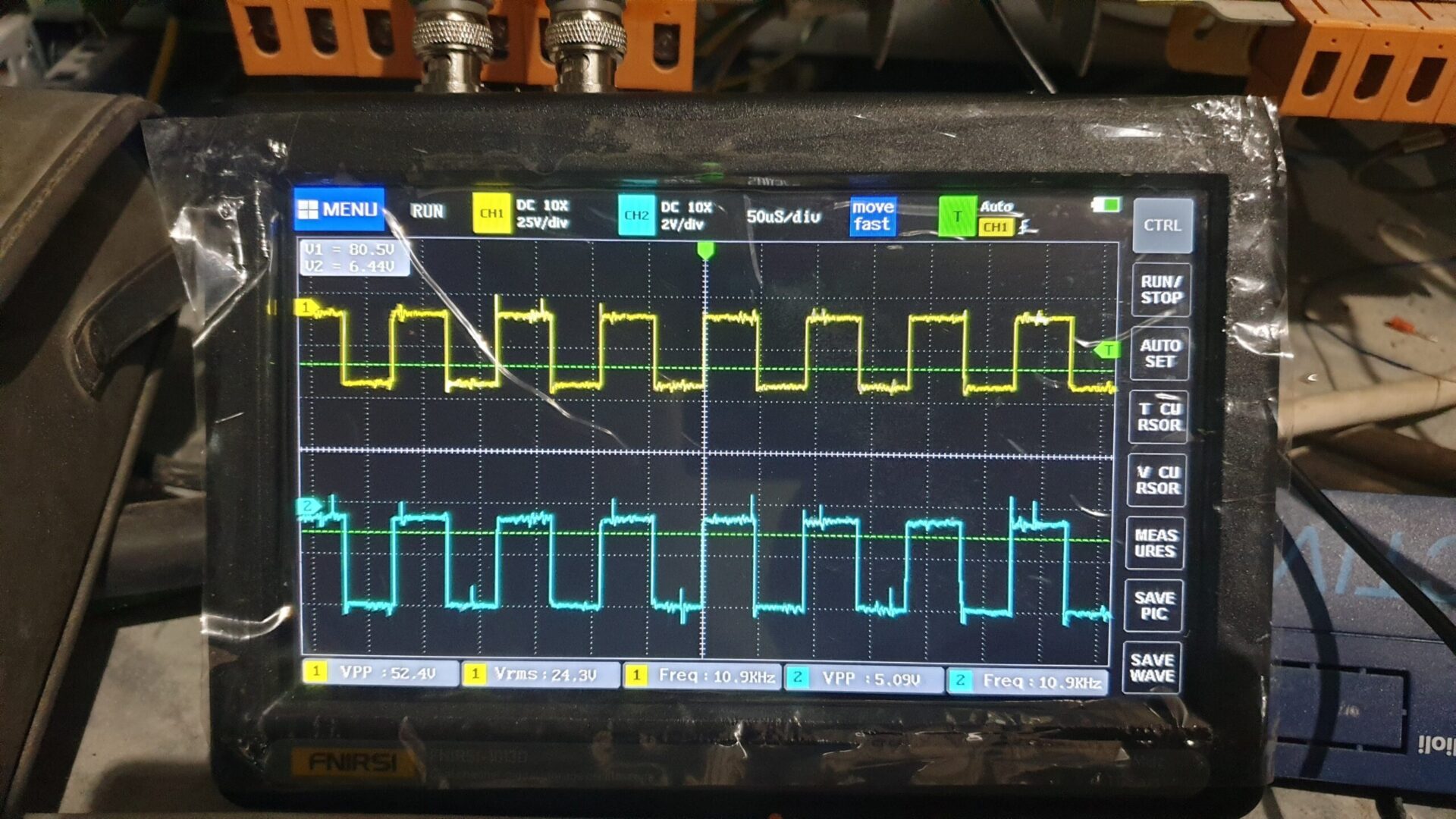

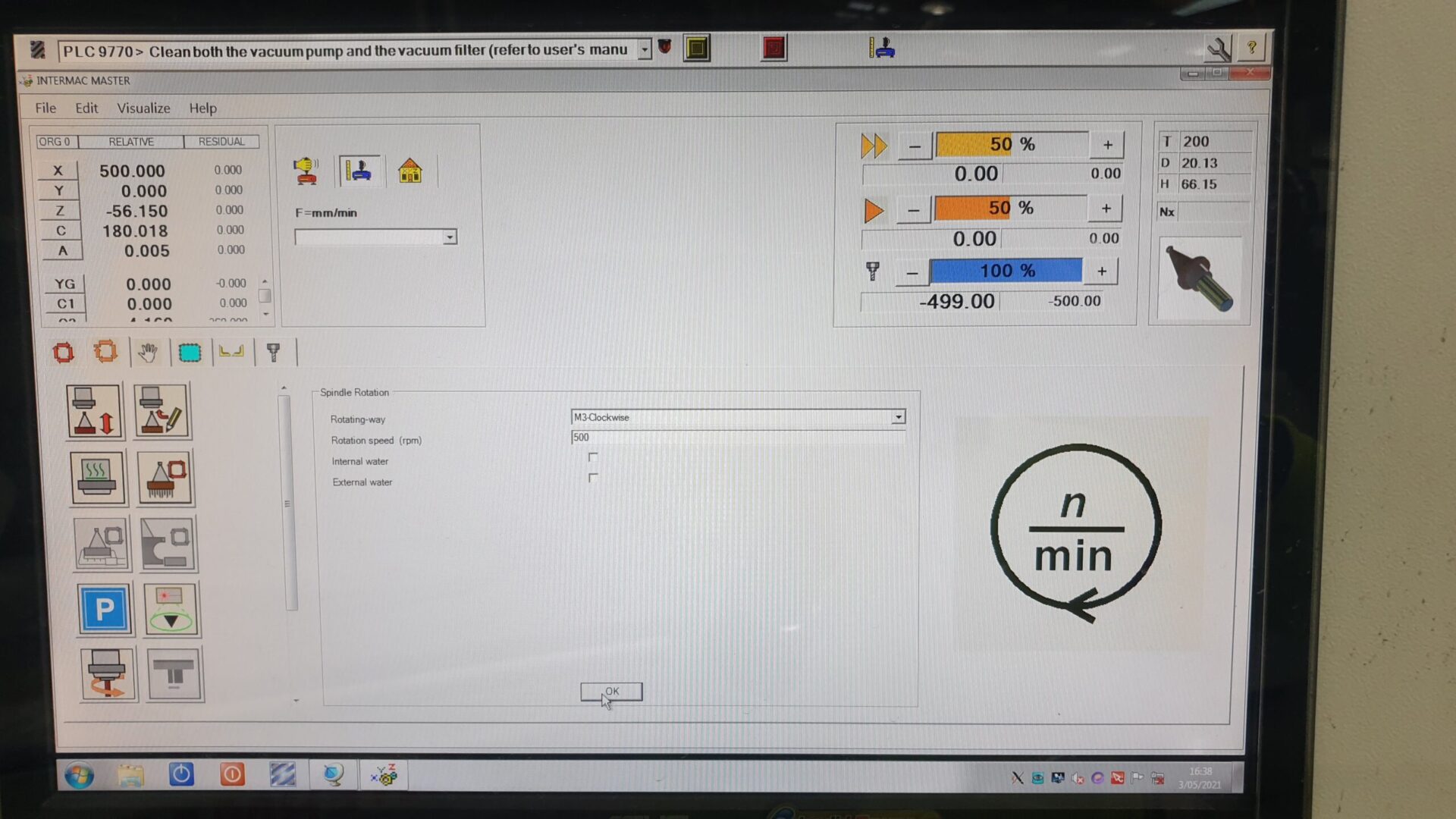

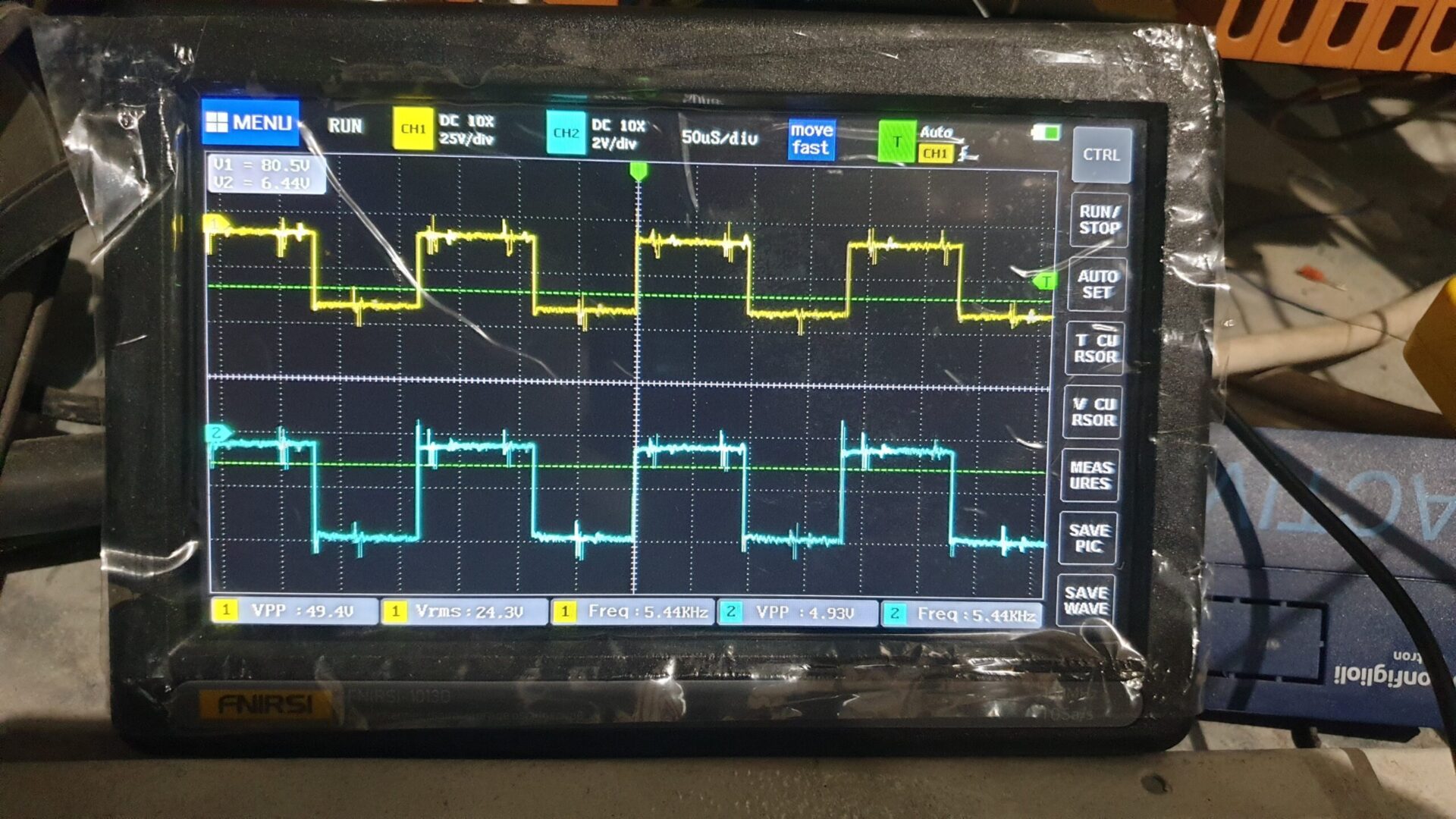

Spindle encoder test

In one case, the spindle encoder on an INTERMAC Master 33, has been tested to verify the function. The test result shown below.

INTERMAC GENIUS CT 61, C axis homing

There was a project for GENIUS CT 61 glass cutting table and the problem was C axis homing.

After the test found that the C axis sensor doesn’t work properly, the sensor changed and the problem disappeared.

INTERMAC Vertmax encoder issue

Another project was related to the encoder problem for a VERTMAX in Revesby, NSW.

There was a problem in the Servopack cable connection which found and solved. Then reset the absolute encoder of the X1 and X2 axis via the USB port of the laptop.

INTERAMC Genius LM 37 Laminate cutting machine, suction bar issue

There was a project in Wyong NSW, regarding a GENIUS LM 37 problem in a suction cup bar.

Suction bar’s actuator had a broken screw and it had to be back in place.

Too many parts have been opened to reach the base, then broken screw replaced, ball bushing mounted in place and all assembly installed very carefully.

Two broken parts have been fixed and the quality of the cut checked, then the happy customer confirmed.

INTERAMC Genius LM levelling issue

Another project was in Milperra, regarding problem in the GENIUS 37 LM cutting table.

Customer complained about too many broken glass in processing.

After proper investigation, problems found in machine leveling. There was up to 5mm error in level.

According to GENIUS 37 LM leveling procedure, the machine has been leveled and the happy customer confirmed.

INTERAMC Genius LM 37 relocation

Next project was relocation of a GENIUS 37 LM cutting inside the factory in New castle.

They wanted to connect LM cutting to a glass loader.

The machine completely opened electrically and put it in three parts. Then one-by-one carried by crane and placed in the right position.

Then everything connected together and started to work.

Happy customer confirmed the whole process of LM cutting and connection to the loader.

INTERAMC CNC Glass tool changing issue

The other project was for a INTERAMC GLASS MASTER 45 regarding an issue in spindle tool changing.

The tool changing sensor and connecting cable have been changed.

Via PLC debug, function of 3 sensors have been checked.

The other project was in Milperra, regarding Excel file import from office software to the cutting table. Below is the exported file from the office quotation software.

I have used power data add-on in Excel 2016 to make a template for converting the exported file to acceptable format of RO Perfect cut, optimisation software.

The converted Excel file was:

And the results in RO Perfect cut:

The customer was very happy with the outcome and currently they use it everyday to automatically send correct panel sizes for GENIUS 37 LM.

INTERMAC Genius LM 37 electrical issue

The other one was in another factory in smithfield, Sydney.

The machine breaks down after a bang and one of the circuit breakers tripps.

It was a 24VDC connection.

After investigation I saw that it goes inside the machine body.

By a tester I checked the resistance of each wire against the power supply and eventually found the cut wire underneath the cutting module.

Then fixed the wire, checked the proper function of the bottom cutting head’s oil lubrication and put it back to normal. Then the happy customer confirmed.

Float cutting table printer issue

Another project was in Condell Park, Sydney, regarding an issue in glass cutting CNC table’s label printing.

The sponge surface of label transfer function was worn out. I realised that extra pressure in label pasting to the glass was the main reason for failure.

Have adjusted the up and bottom position of label carriage and send an order to spares for sending a brand new sponge.

Customer was happy later that day and we changed the worn out sponge in about 10 days after arrival.

INTERMAC Vertmax tool changing issue

A VERTMAX glass vertical milling & drilling CNC, had an issue in the rotary tool changer.

Every electrical and pneumatic aspect of the issue already been checked and found that something is wrong inside the X movement of rotary tool changer.

I have started to reach the rod-less cylinder.

After opening I figured out the pin unscrewed by itself and remained inside the cylinder connection.

It’s been put back, whole assembly checked and fine tuned.

Tool changing and whole machine work has been confirmed with the happy customer.

INTERMAC Vertmax Spindle tool changer issue

The other project was in Melbourne for a VERTMAX vertical milling and drilling CNC work center. He heard an air leakage from the spindle back and the tool changer doesn’t work any more, the client said.

I started to reach that point according to the procedure and had to open too many parts very carefully and the machine was still under warranty.

Have reached it, fixed and tested it many times, took a video to make sure that works properly.

Everything was put back very careful and paid too much attention sealing the entire assembly against water.

Checked with many samples, minor issues solved and happy customer confirmed.

INTERMAC Vertmax water pump repair

Next project in Melbourne was for a VERTMAX. It had a leakage problem in the main water pump.

The machine was under warranty and the repair kit was sitting there awaiting replacement.

Have replaced the seal kit according to the procedure and leakage disappeared. It has been confirmed by the happy customer.

INTERMAC Master preventive maintenance

There was a project for preventive maintenance in for a MASTER 43 V, which was very good with a positive outcome for that customer.

INTERMAC Genius machines preventive maintenance

Another PM project was in Wyong for GENIUS 37 LM, GENIUS 37 CT and their glass sheet storage system.

Maintenance done according to the procedures and any necessary recommendations from the user manual.

Some minor issues solved and worn parts have been changed.