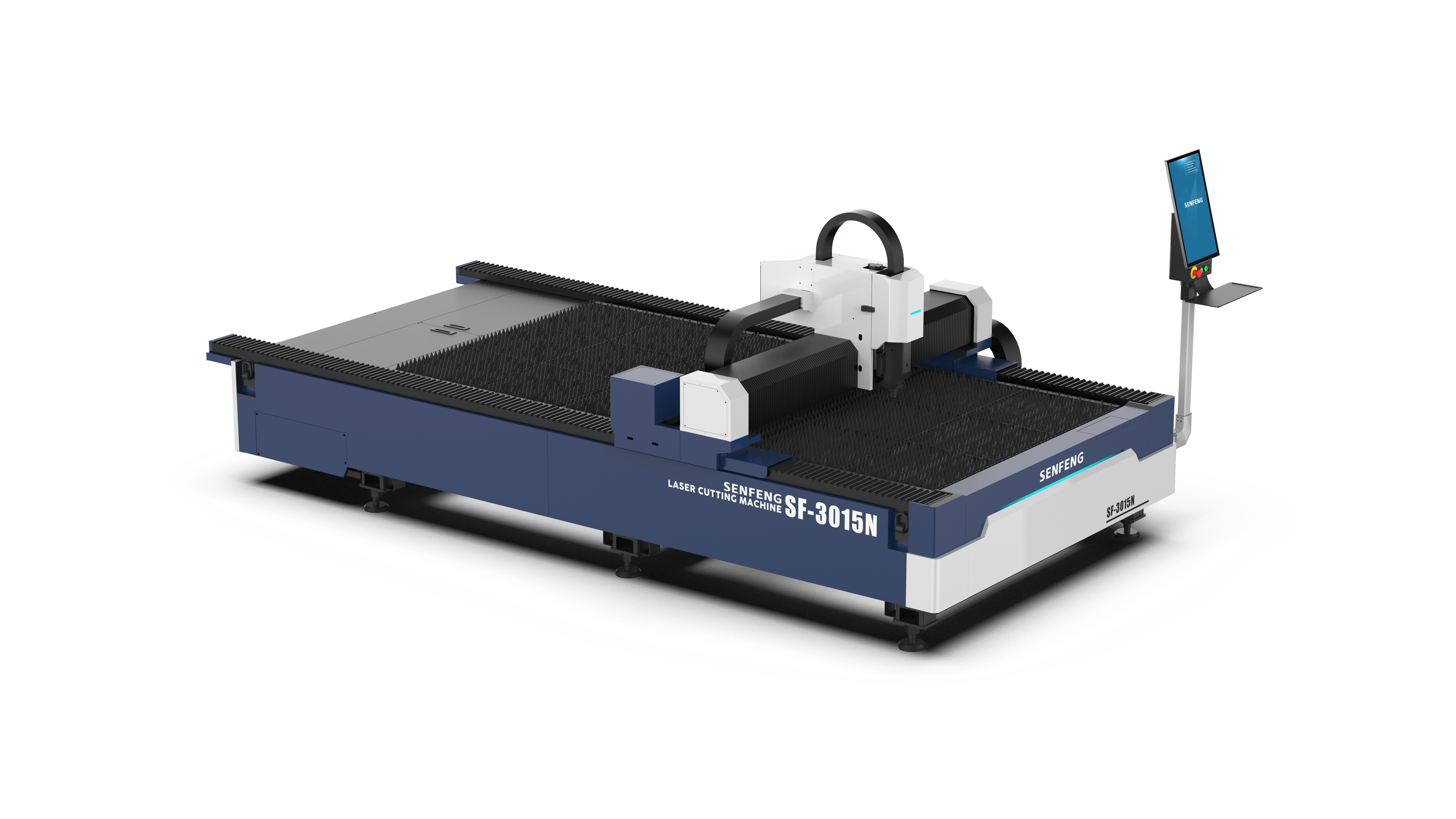

In this post, we will explore the various parameters that influence the quality of final product in fiber laser machine.

Other researchers suggested enhancements here, here, here and here

Cutting speed of fiber laser machine

The effects of excessive cutting speed on quality:

- It may result in incomplete cuts and sparks flying.

- Some areas may be cut, while others remain uncut.

- The cut section may appear rough, but no melt stains are present.

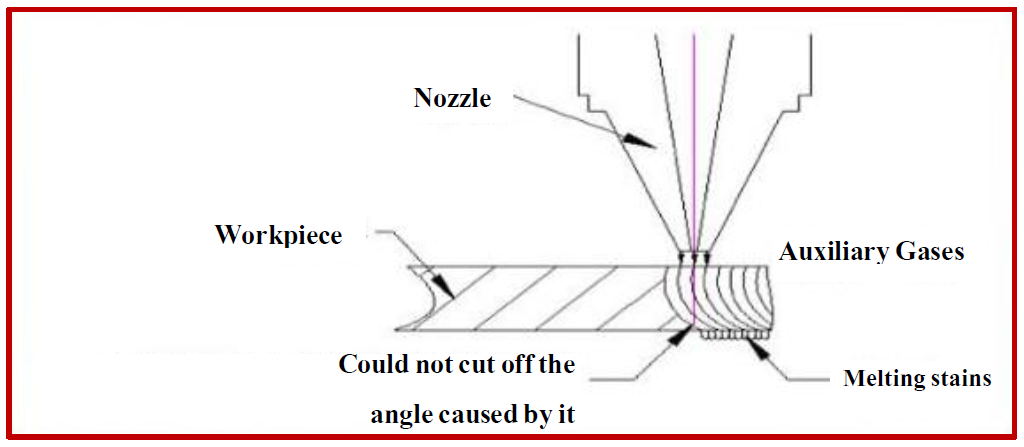

- An overly fast speed can prevent the plate from being cut properly, leading to angled cuts and melt stains on the lower half of the section, as shown in the image below.

Impact of Excessively Slow Cutting Speed on Quality

- The plate being cut will overheat, resulting in a rough cut surface.

- The cutting seam will widen, leading to excessive melting in the smaller rounded or sharp corners, preventing an ideal cutting result.

- The cutting efficiency will decrease, negatively impacting overall production capacity.

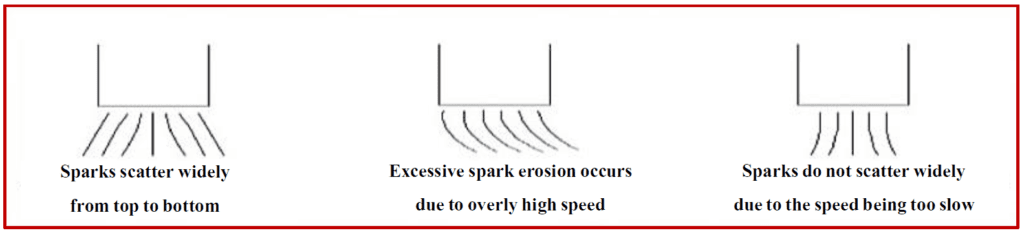

The cutting speed can be assessed by observing the sparks produced, allowing for the selection of an optimal cutting speed.

- When the cutting speed is optimal, the sparks disperse evenly from top to bottom

- When the cutting speed is too fast, the sparks lean at an angle

- When the cutting speed is too slow, the sparks appear small, concentrated, and lack proper dispersion

Focus of fiber laser machine

The focal position plays a crucial role in laser cutting. Selecting the right focus affects both plate drilling and the quality of the cutting section. Here’s how to choose the optimal focus and its impact on the process

For stainless steel, nitrogen cutting typically uses a negative focus, while for carbon steel, oxygen cutting generally requires a positive focus

Name and focus position

Cutting materials and cross-section characteristics

Zero focal length: The laser focus is on the surface of the cutting workpiece

Ideal for carbon steel thinner than 1mm;

The focus is set on the workpiece surface, resulting in a smooth upper surface but a rough lower surface

Negative focal length: The laser focus is below the surface of the cutting workpiece

In nitrogen cutting for stainless steel, the focus is set below the plate surface, resulting in a wider smoothing range and a broader kerf compared to zero focus. The gas flow is higher during cutting, and the perforation time is longer than with zero focus.

Positive focal length: The laser focus is above the surface of the cutting workpiece

Used for oxygen cutting of carbon steel, resulting in a blackened surface and a rough cross-section

Nozzle

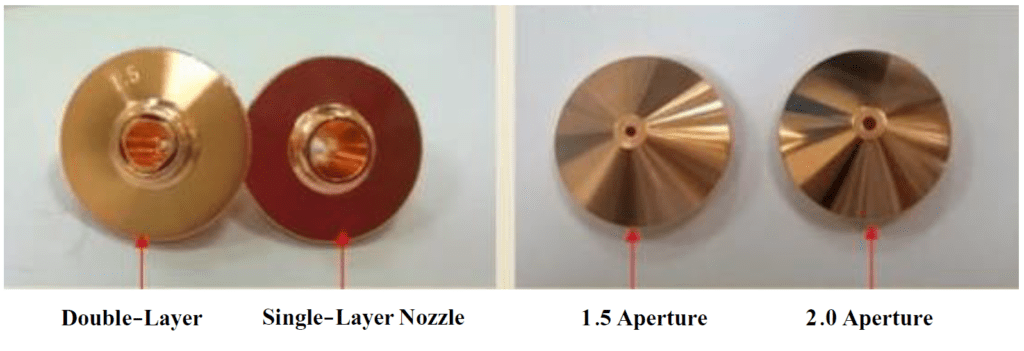

The commonly used nozzle apertures are 1.0, 1.5, 2.0, and 2.5. The differences in aperture size are as follows:

- When cutting thin plates:

- A 1.5mm nozzle produces a finer cutting surface.

- A 2.0mm nozzle results in a coarser cutting surface with melt stains at the corners.

- When cutting thick plates:

- Due to higher cutting power, heat dissipation takes longer, and cutting time increases.

- A 1.5mm nozzle has a small gas diffusion area, making it less stable.

- Nozzles larger than 2.0mm provide a larger gas diffusion area and slower gas flow, ensuring more stable cutting.

Nozzle aperture

Gas flow rate

Melt removal capability

Small

Fast

Strong

Big

Slow

Weak

Nozzles are categorized into double-layer (1.5, 2.0) and single-layer (1.5, 2.0) types.

- Oxygen cutting for carbon steel:

- Typically, double-layer nozzles are used.

- For thicknesses under 3mm, a single-layer 1.5mm nozzle is preferred.

- For 3-12mm, a double-layer 2.0mm nozzle is commonly used.

- Nitrogen cutting for stainless steel:

- Generally, single-layer nozzles are used.

- For thicknesses under 2mm, a single-layer 1.5mm nozzle is recommended.

- For thicknesses over 2mm, a single-layer 2.0mm nozzle is used

The nozzle aperture size has a significant impact on both cutting and perforation quality. A larger nozzle aperture provides less protection for the focusing lens, as molten sparks generated during cutting are more likely to bounce upward, reducing the lens’s lifespan.

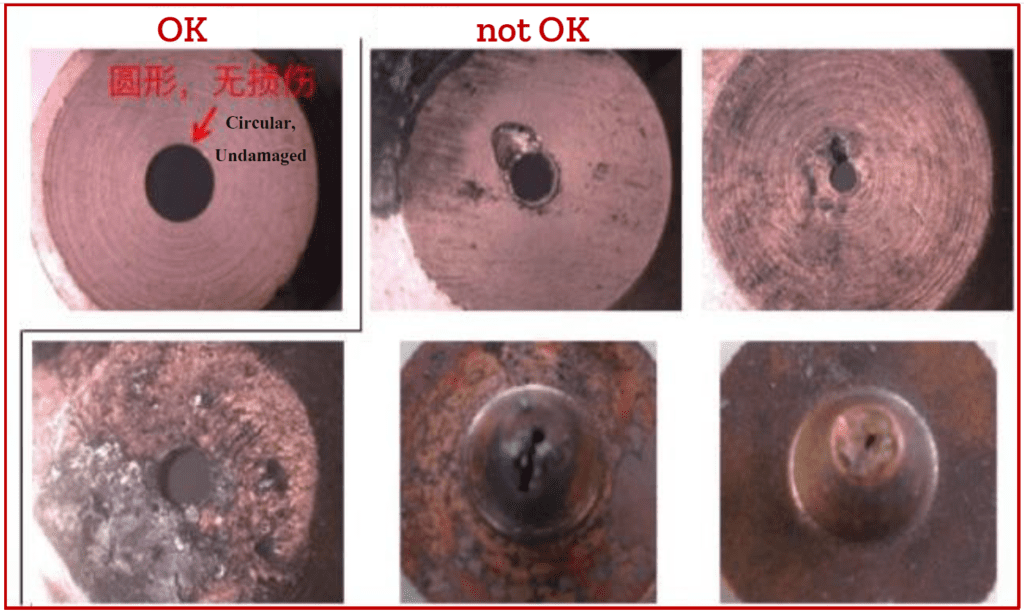

Additionally, nozzle quality is a crucial factor in achieving optimal cutting performance. The required nozzle shape specifications are shown in the figure below

Air Pressure

The primary functions of cutting gas include cooling and protection. Oxygen aids in combustion and heat dissipation, efficiently removing molten debris during cutting. It also prevents molten splatter from rebounding into the nozzle, protective lens, collimator, and focusing lens, ensuring optimal performance and longevity of the equipment.

Influence of Cutting Gas and Pressure on Cutting Quality

1. Role of Cutting Gas

Cutting gas aids in cooling, heat dissipation, and combustion while effectively removing molten debris, resulting in a cleaner and higher-quality cutting surface.

Effects of Insufficient Gas Pressure

- Inadequate gas pressure leads to excessive molten stains during cutting.

- The cutting speed cannot be increased, reducing overall production efficiency.

Effects of Excessive Gas Pressure

- High pressure creates excessive airflow, leading to a rough cutting surface and a wider kerf.

- Excessive airflow may cause partial melting of the cutting section, preventing the formation of a clean, precise cut.

Influence of Cutting Gas Pressure on Perforation

Effects of Low Gas Pressure

- Insufficient gas pressure makes it difficult for the laser to penetrate the material.

- Increased drilling time lowers productivity.

Effects of High Gas Pressure

- Excessive pressure causes the penetration point to melt, leading to burst holes and larger molten areas, negatively impacting cutting quality.

Optimal Gas Pressure for Laser Drilling

- Higher gas pressure is typically used for drilling thin plates.

- Lower gas pressure is preferred for drilling thick plates.

Gas Pressure Considerations for Different Materials

- Oxygen cutting of carbon steel: Thicker materials require lower gas pressure.

- Nitrogen cutting of stainless steel: Thicker materials require higher gas pressure, typically maintained above 1.2

Adjustment of coaxially (center point)

Stick transparent tape over the nozzle opening.

Set the laser to 10%-20% power and fire a test shot.

Remove the tape while keeping its orientation for comparison with the nozzle.

- Normally, a small burn mark should appear on the tape, indicating the laser’s center.

- If no mark is visible, the laser beam may be misaligned and hitting the nozzle.

If the burn mark varies in size, check for consistent test conditions and ensure the focusing lens is secure.

No comment