What Are CNC Machinery Applications?

In this page we talk about CNC machinery applications in different industries.

What can i do with a cNC router?

Wood carving, cutting and shaping, acrylic machining, Aluminum products manufacturing and even Vinyl cutting can be done with a simple 3-axis router!

What is CAD-CAM?

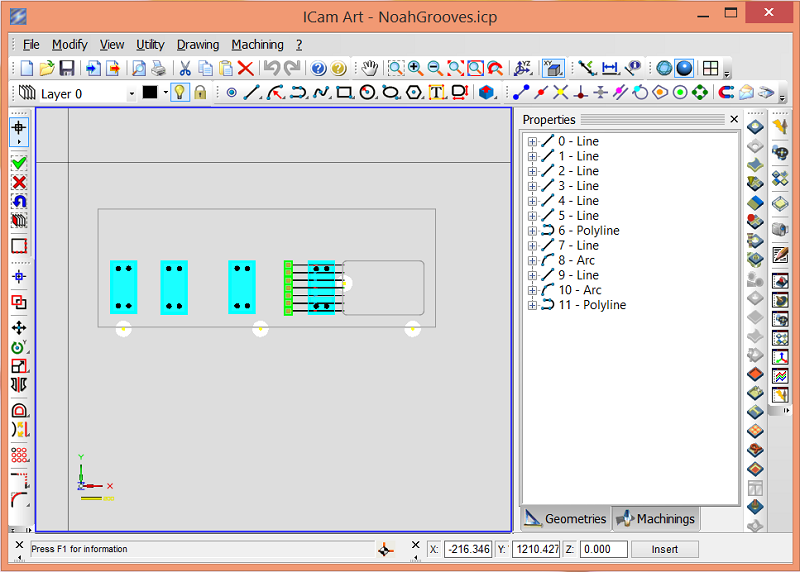

CAD is computer aided design. Softwares like AutoCAD, LibreCAD, … to make the shape in computer and specify the dimensions. CAM is computer aided machining. Usually, you choose tools and machining strategy in CAM softwares, like LazyCAM, CAD2CNC, … .

Some products like ArtCAM, INTERMAC ICAM, … have their own CAD/CAM package. Which means you do drawing and machining in the same platform.

Which machinery do i need to open a signage business?

Basically, it starts with printers!. Big UV color printer of course is an advantage for your business. For making great 3D signs you need to have a 3-axis router and/or a CO2 laser cutting/engraving machine.

You can process both acrylic and aluminum with a CNC router. Of course, stainless steel signs, not too thick, can be cut and engrave with your CO2 laser machine.

What can i do with a CO2 laser machine?

You can cut acrylic sheets, timber and thin MDF, thin stainless and mild steel and of course aluminum.

CO2 laser machine is a perfect solution for engraving and signage on almost all materials!

Which machine shall i use for stainless steel and mild steel sheets cutting?

Fiber laser cutting CNC machinery for Sure!

Fiber-to-Fiber, compact solid state design configuration is maintenance free, much faster than CO2 for metal cutting and much effective absorption characteristic due to the shorter wavelength of the Fiber laser.

The higher absorption of the Fiber wavelength and the higher power density created by the focused beam combine to achieve up to a five time increase in cutting speeds in materials that are less than 1/4 inch thick.