All the machines described in this article are monoblock, which means no construction or concrete work needed for machine installation.

What is a Stone Bridge Saw and How Does it Work?

A stone bridge saw is a specialized piece of equipment used in the stone fabrication industry, particularly in the cutting and shaping of natural and engineered stone materials. This machine is designed to make precise cuts in stone slabs or blocks, allowing for the creation of custom shapes, countertops, and other stone products. Here’s an overview of what a stone bridge saw is and how it works:

Components of a Stone Bridge Saw:

- Bridge and Rails:

- The machine typically consists of a sturdy bridge that spans across a set of rails. This bridge houses the cutting mechanism and moves along the rails to facilitate precise cuts.

- Worktable:

- A worktable supports the stone slab or block during the cutting process. The stone is securely fixed in place to ensure stability and accuracy.

- Cutting Head:

- The cutting head is a crucial component that houses the saw blade. It is mounted on the bridge and can move in multiple directions, allowing for versatile cutting capabilities.

- Saw Blade:

- Stone bridge saws are equipped with diamond-tipped saw blades designed specifically for cutting through hard stone materials. The diamond blades can vary in diameter and are chosen based on the type and thickness of the stone being cut.

- Water System:

- To reduce heat generated during the cutting process and minimize dust, stone bridge saws often incorporate a water system. Water is sprayed onto the cutting area, serving to cool the blade and suppress the formation of dust.

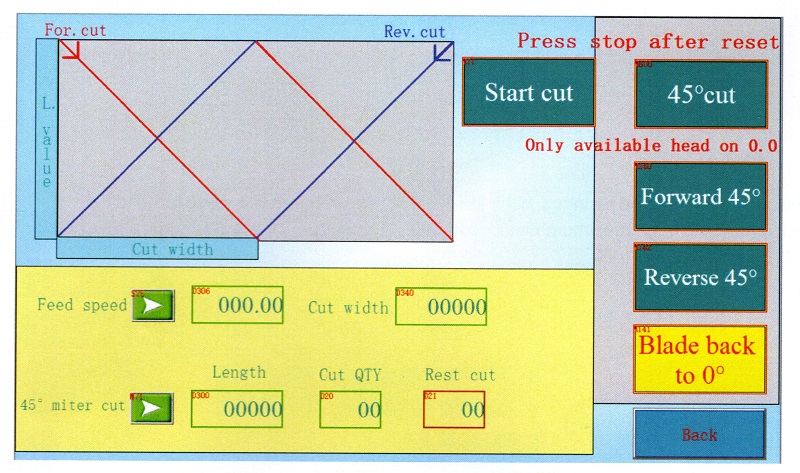

- Control Panel:

- Modern stone bridge saws are typically equipped with a user-friendly control panel that allows operators to program and control the cutting process. This includes setting the dimensions of the cut and controlling the movement of the cutting head.

How a Stone Bridge Saw Works:

- Setup:

- The stone slab or block is securely placed on the worktable, ensuring stability during the cutting process.

- Programming:

- Operators input the desired dimensions and specifications into the control panel, specifying the type of cut needed.

- Blade Engagement:

- The cutting head, which houses the diamond-tipped saw blade, is positioned over the stone. The blade is then engaged and begins to rotate.

- Cutting Process:

- The stone bridge saw moves the cutting head along the predefined path, guided by the operator’s input. The diamond-tipped saw blade makes precise cuts through the stone, shaping it according to the programmed specifications.

- Water Cooling:

- Throughout the cutting process, water is continuously sprayed onto the cutting area. This serves to cool the saw blade, preventing overheating, and also helps to control dust generated by the cutting action.

- Completion:

- Once the cutting process is complete, the stone slab or block is removed from the worktable, and the cut edges are inspected for accuracy and smoothness.

Stone bridge saws are essential tools in stone fabrication shops and kitchen countertops manufacturing, providing a high level of precision and efficiency in creating custom stone products. They are widely used in the production of countertops, tiles, monuments, and various architectural and artistic stone applications.

Ganger CNC

Ganger CNC catalog can be viewed here

Different saw designs

There are different saw types in terms of mechanical movements and control system.

4 axis bridge saw

The simplest practical saw in our range is 3220A, which has 3200*2000 mm working table and C axis rotation for different cut directions. It’s ideal for high speed slab cutting of straight jobs.

Complete product description is here

4 Axis bridge saw with mitre

In this version is possible to cut straight and 45 degree cuts. This machine also cuts mitre 45° in front and left side.

In fact hydraulic actuator added to this version for head tilting to cut mitre.

Technical features of 3220B saw described here

Upgraded GQ-3220B+

4 axis bridge saw for straight and mitre cut on four sides,

The other name of GQ-3220B+ is GQ-3220H

5 axis CNC bridge saw

This version of our saw takes advantage of PC based CNC control.

Any shape can be processed with 3220D saw in manual size input, shape library, nesting and DXF file import modes.

This machine is a only version with milling cutter for internal cut outs like cooktop and under mount.

In the following video the internal cutting with milling and disk demonstrated.

The product detailed description is here

GQ-3220DS 5 axis CNC bridge saw with camera

Ganger new product is this 5 axis bridge saw with suction cup movement and camera

European machines

Donatoni , Intermac

Donatoni CNC stone cutting machine now is part of Intermac group.

This product explained more in detail here

Breton

Breton is the first engineered stone manufacturer and one of the biggest market leaders in stone.

Breton GENYA stone cutting machine details are here