some projects on BIESSE woodworking CNC machines

Biesse CNC machines are widely used in NSW because of the local support and service team. Biesse Rover is very popular in NSW kitchen and interior supply factories.

Biesse Rover Relocation from Wetherill Park to Sefton, NSW

As shown in the video, the machine came back to work after relocation to Sefton.

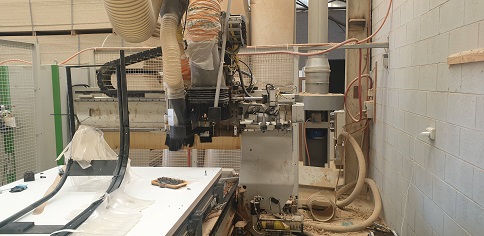

BIESSE Skill Ball screw repair in Bankstown, NSW

Biesse SKILL Z axes ball screw dismantling

First was needed to remove the safety guards, dust collector box, sensors and air blowers to reach the part. The Z axes servo motor removed to reach the ball screw bracket, as shown above. After undoing the bracket and the ball screw nut’s screws, the ball screw shaft can be pulled out downward.

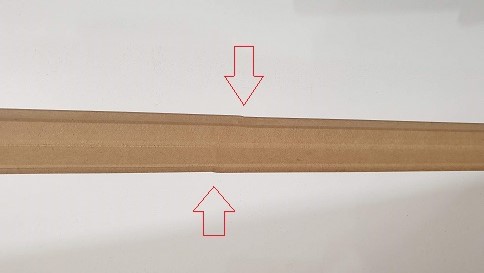

biesse Rover misalignment in grooves

The customer mentioned misalignment in groove cutting for doors and wardrobes.

After close look and more investigation the problem found in X axes excessive backlash. As shown in the following photo, there was too much dust and grease contamination on the rack and pinion.

After cleaning the rack and pinion and readjusting the gear gap, the problem solved.

Biesse Rover B Relocation in Seven hills, NSW

The following photos show the machine before relocation.

The machine has been disconnected according to the manufacturer’s guide lines and made ready for loading.

Franna crane has been used for loading and relocation.

Spindle kit replacement on a Biesse Rover B

The job was replacing a seized spindle’s kit. A complete bearing part and stator was supplied through HSD company for service, instead of replacing the whole spindle, which named spindle kit.

The job started with removing the air blowers, sensors and dust collection box, to access the spindle.

The most important feature of the spindle kit is the ease of replacement in correct direction and taking advantage of the puller screws. No need to worry about the tool locking unit or other inside parts, just pull out the bearing unit downward.

Do not forget the last cone inside the collet and replace the spindle kit, this convenient way!

Rover B 4,35 FT ball screw repair in Seven Hills, NSW

The problem was damaging the ball screw nut return part. almost all balls escaped from the nut and we had to replace brand new balls.

Special super glue and some small plastic parts have been used to repair and restore the ball return mechanism.

The other option was replacing the whole shaft and nut with different ball screw brand. Then needed to machine the ball screw shaft and size it correctly.

Here is the link to Biesse Australia spare parts, for your reference.

SCM Woodworking CNCs

SCM is the other major brand in Woodworking machinery in NSW. Some or our projects on SCM machine described here