Precise sheet cutting CNC, non-stop

Medium power, smaller in size, rich in functions

Fiber laser cutter is a CNC machine for metal sheet precise cutting. Mainly for stainless steel, galvanized, mild steel, aluminum and brass.

This machine features an open design for easy loading and unloading. Its compact structure utilizes a single platform, occupying only 12m² of space.

Laser welding machine and this fiber laser cutting, can possibly provide ideal equipment for precise sheet metal manufacturing.

SF3015N Technical Parameters

| Item | Parameter | ||||

|---|---|---|---|---|---|

| Power | 1.5kW | 2kW | 3kW | 4kW | 6kW |

| Work area (L*W) (mm) | 3000*1500 | ||||

| X-axis travel (mm) | 1530 | ||||

| Y-axis travel (mm) | 3050 | ||||

| Z-axis travel (mm) | 80mm | ||||

| X/Y axis positioning accuracy (mm) | ±0.05mm | ||||

| X/Y axis repeated positioning accuracy (mm) | ±0.02mm | ||||

| Maximum speed (m/min) | 100m/min | ||||

| Maximum acceleration (G) | 1.0G | ||||

| Dimensions (L*W*H) mm | 4360*2760*1800 | ||||

| Maximum load (KG) | 1100 | ||||

| Weight (KG) | 1790 | 1810 | 1830 | 1860 | 1920 |

| Phase | Three-phase | ||||

| Power supply rated voltage (V) | 380V | ||||

| Frequency (HZ) | 50HZ | ||||

| Overall power supply protection level | IP54 | ||||

Just as an indication, a 3Kw machine can cut 1mm carbon steel at 35m/min, with air pressure, which is quite fast.

The same machine cuts 1mm stainless steel at 45m/min under N2 gas and 1mm aluminum at 30m/min.

SF3015N Cutting Parameters

| Material | Thickness (mm) | 1.5kW | 2kW | 3kW | 4kW | 6kW | Gas |

|---|---|---|---|---|---|---|---|

| Stainless steel | Cutting speed (m/min) | ||||||

| 1 | 23-30 | 30-35 | 30-45 | 40-50 | 45-55 | N2/Air | |

| 2 | 7.0-12 | 10- 15 | 20-25 | 25-30 | 30-35 | N2/Air | |

| 3 | 4.5-5.5 | 5.0-6.5 | 8.0- 10 | 9.0- 13 | 18-22 | N2/Air | |

| 4 | 2.0-2.5 | 4.0-5.0 | 5.0-6.0 | 7.0-9.3 | 10-14 | N2/Air | |

| 5 | 1.4- 2.0 | 2.0-2.3 | 3.0-3.6 | 4-4.5 | 8.0- 10 | N2/Air | |

| 6 | 1.0- 1.2 | 1.5-2.0 | 2.0-3.0 | 3.5-4.5 | 4.3-5.0 | N2/Air | |

| 8 | 0.8-1.2 | 1.0- 1.5 | 2.0-3.0 | 3.0-4.0 | N2/Air | ||

| 10 | 0.5- 1.0 | 1.2- 1.6 | 1.8-2.5 | N2/Air | |||

| 12 | 0.4-0.6 | 0.8- 1.2 | 1.0-1.5 | N2/Air | |||

| 14 | 0.8-1.2 | N2/Air | |||||

| 16 | 0.6-1.0 | N2/Air | |||||

| 20 | 0.4-0.7 | Air | |||||

| Carbon steel | 1 | 23-26 | 25-35 | 30-40 | 35-45 | 40-45 | N2/Air |

| 2 | 4.2-6.5 | 10- 15 | 15- 20 | 15-20 | 20-28 | N2/Air | |

| 3 | 3.0-4.5 | 3.5-5.5 | 3.5-4.5 | 7.0-9.0 | 12-17 | N2/Air | |

| 4 | 2.3-3.0 | 3.0-3.2 | 3.0-3.5 | 3.0-4.0 | 8.0- 10 | N2/Air | |

| 6 | 1.7-2.5 | 2.0-2.7 | 2.5-3.5 | 2.0-3.0 | 2.5-3.3 | O2 | |

| 8 | 1.2- 1.6 | 1.3-1.7 | 1.8-2.3 | 2.0-3.0 | 2.3-3.0 | O2 | |

| 10 | 1.0- 1.2 | 1.0- 1.6 | 1.4-1.8 | 2.0-2.5 | 2.0-2.5 | O2 | |

| 12 | 0.8- 1.0 | 0.8-1.2 | 1.0- 1.4 | 1.5- 2.0 | 1.8-2.2 | O2 | |

| 14 | 0.6-0.7 | 0.8-1.0 | 0.8- 1.0 | 1.0- 1.5 | 1.4-1.7 | O2 | |

| 16 | 0.5-0.6 | 0.7-1.0 | 0.7- 1.1 | 0.7- 1.2 | 1.0-1.6 | O2 | |

| 20 | 0.5-0.7 | 0.6-0.8 | 0.6-1.2 | O2 | |||

| 25 | 0.4-0.6 | 0.5-0.7 | O2 | ||||

| 30 | 0.4-0.6 | O2 | |||||

| Brass | 1 | 15-20 | 15-25 | 25-30 | 30-35 | 40-45 | N2/Air |

| 2 | 4.8-6.0 | 8.0- 11 | 12- 17 | 15- 18 | 20-25 | N2/Air | |

| 3 | 1.5-2.0 | 3.0-4.5 | 5.0-6.0 | 8.0-10 | 12-15 | N2/Air | |

| 5 | 0.5-0.7 | 1.3-1.7 | 1.8-2.5 | 3.0-4.0 | 5.0-6.0 | N2/Air | |

| 6 | 0.6-0.8 | 0.8- 1.0 | 2.0-2.5 | 3.0-4.0 | N2/Air | ||

| 8 | 0.8- 1.2 | 1.5-2.5 | N2/Air | ||||

| 10 | 1.0-1.5 | N2/Air | |||||

| 12 | 0.8-1 | N2/Air | |||||

| Aluminum | 1 | 15-23 | 20-25 | 30-35 | 35-40 | 50-55 | N2/Air |

| 2 | 6.0-8.0 | 10- 15 | 14-20 | 17-25 | 25-30 | N2/Air | |

| 3 | 2.0-3.0 | 4.0-5.0 | 8.0- 10 | 10-13 | 13-16 | N2/Air | |

| 4 | 1.0- 1.7 | 2.0-2.5 | 5.0-6.5 | 6.0-7.5 | 10-13 | N2/Air | |

| 5 | 0.5-0.8 | 1.0-2.0 | 2.5-3.5 | 4.0-5.0 | 5.0-6.0 | N2/Air | |

| 6 | 0.6- 1.0 | 1.2- 1.5 | 2.5-3.5 | 3.0-4.0 | N2/Air | ||

| 8 | 0.7- 1.3 | 1.0-2.0 | 2.0-3.0 | N2/Air | |||

| 10 | 0.8-1.2 | 1.0-2.0 | N2/Air | ||||

| 12 | 0.4-0.6 | 0.7-1.2 | N2/Air | ||||

| 14 | 0.5-1.0 | N2/Air | |||||

| 16 | 0.4-0.6 | N2/Air | |||||

SF3015N Laser Source

1. High-power and high-quality laser output

2. Uniformly distributed beam energy

3. Excellent performance and strong processing ability

4. Compact structure and maintenance-free

5. Wide range of applications

SF3015N Laser Cutting Head

3kW and below

4kW-6kW

1. Efficient Cooling: Cooling structures for collimating and focusing lenses, plus extra cooling airflow for nozzle, extends operating time.

2. Rapid Focusing: Collimating focus adjustment offers faster focal point movement and a wider focusing range compared to focusing adjustments.

3. Multiple Protective Lenses: Four protective lenses reduce contamination during fiber and lower lens replacement, extending the life of collimating and focusing lenses.

4. Optimized Structure: Integrated body design ensures sealing. Improved QBH, QD, and G5 fiber interfaces enhance laser compatibility and prevent issues like rust from leaks.

SF3015N Machine Bed System

Tube Welding Bed

The reinforced welded bedframe is designed for high-speed movement, with aging treatment to ensure precision and stability during long-term operation.

The bedframe undergoes annealing to eliminate internal stress and increase rigidity, followed by secondary vibration aging treatment and precision machining.

The semi-hollow bedframe structure reduces thermal deformation, extends service life, and ensures cutting accuracy.

High-strength Aluminum Alloy Beam

The high-strength aluminum alloy beam is lightweight and offers excellent dynamic performance.

The beam is precision-machined after secondary vibration aging treatment, ensuring its overall strength and stability.

Automatic Focus System

Equipped with an automatic focusing laser head, the machine adjusts the focus to the optimal cutting distance based on material type and thickness, enhancing efficiency.

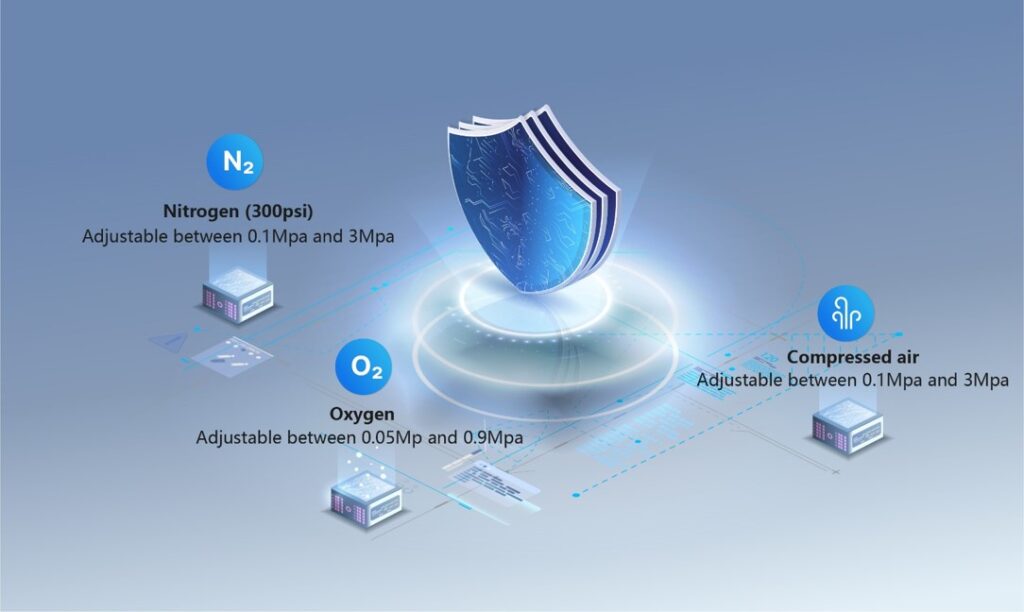

Pneumatic system

The pneumatic system is equipped with AVENTICS control valves and proportional valves, allowing electrical control of pressure and flow for each gas.

Cutting auxiliary gases (O2, N2, compressed air, etc.)

Auto Gas Distribution System

The CNC laser cutting machine has two separate gas lines: nitrogen (air) and oxygen. Each gas line can be independently controlled for flow rate and pressure.

•The equipment software terminal is equipped with an automatic auxiliary gas selection feature.

•The type and pressure of auxiliary gases can be automatically set and selected through the CNC program, eliminating the need for manual operation.

•The actual gas pressure at the cutting head outlet can be easily read and displayed on the panel in real-time.

Advantages of Fiber Laser Cutting Technology

The Primary Advantages Of Cutting Flat Sheet Metal With Fiber Laser Technology Are Derived From Its Monolithic, Fiber-To-Fiber, Compact Solid State Design Configuration That Is Maintenance Free And Provides A Lower Cost Of Operation Than Can Be Achieved With Comparable CO2 Lasers.

Fiber laser beam characteristics also provide for much faster cutting speeds than CO2 lasers.

The focused beam of even a 2 kW Fiber laser demonstrates a 5X greater power density at the focal point when compared with a 4 kW CO2 laser. It also possesses a 2.5X greater absorption characteristic due to the shorter wavelength of the Fiber laser.

The higher absorption of the Fiber wavelength and the higher power density created by the focused beam combine to achieve up to a five time increase in cutting speeds in materials that are less than 1/4 inch thick.

Fiber laser cutting systems can certainly cut up to one-inch thick with higher Fiber laser powers and even cut faster when utilizing nitrogen as the assist gas, but the “sweet spot” where the most significant benefits are realized is in the 5/16 inch and under range for steel when making comparisons with CO2 systems. For certain, if you are processing stainless, aluminum, brass or copper materials, Fiber laser technology is the fastest and most economical regardless of thickness.