ZX9325P Glass Polish Machine is straight line glass edge polishing machine for shower screens, splash backs, pool fencing and table tops.

The machine is for grinding/polishing bottom edge of flat glass, with arris grinding.

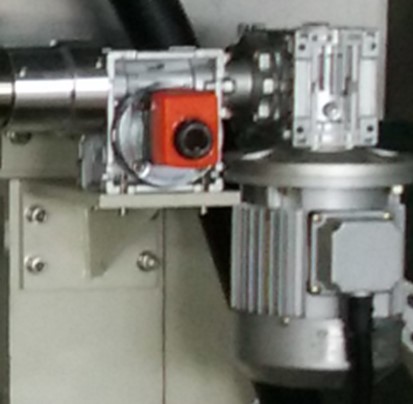

Testing Polish Machine ZX9325P in the factory

glass polish machine Structure:

The machine is composed of four parts: mechanical parts, electrical cabinet, glass support rack and infeed/outfeed conveyors.

Conveyor:

chain transmitting system,pads are connected by the two chains. Pads are made of nylon, stretchy rubber pad is attached on the nylon base.

The machine has a reinforced middle support. This has an important role to rectify the conveyor straightness in case it get some deformation in a long run.

Basement, support, conveyor, :

Aremade of cast iron to ensure stability and solidity

Front rail movement:

driving by motors and move in parallel to adapt to different glass thickness, glass thickness is shown on mechanical meter.

glass polish machine Working speed adjustment:

through speed regulator (drive motor), manually, the speed is shown on digital meter. The drive motor made by Starlight company, which is a high quality factory in China.

This machine takes advantage of high quality CDQC motors

Glass support frame is Aluminum bar with plastic roller.

Water system

Water is circulated in the machine and stainless water tank. Wheel tank outlets connect with one stainless drain pipe which is very easy for installation. The square water tube for water inlet is connected with each wheel nozzle.

Amperemetre:

check the wheel absorption.

Infeed and outfeed conveyors use timing belt. Glass removal can be adjusted by a mechanical system on loading conveyor.

Spindles for arris adopts drag plates structure, which has no vibration in working.

Technical Specifications:

| Spindles | 9 heads. |

|---|---|

| Working speed | 0.8-4.0m/min |

| Grinding depth | 3mm |

| Max. arris width | 2.5mm |

| Min. glass size | 80mmx80mm |

| Glass thickness | 3-25mm |

| Total power | 18kw |

| Total dimension | 6.9x1.0x2.5m |

| Total weight | 3000kg |

Configuration of grinding wheels:

| Wheel position | Type of wheel | internal diameter (mm) | external diameter (mm) | Grain (mesh) | Power (kw) | Control |

|---|---|---|---|---|---|---|

| No.1 | Diamond wheel | 12 | 150 | 100 | 2,2 | Mechanical |

| No. 2 | Diamond wheel | 12 | 150 | 230 | 2.2 | Mechanical |

| No.3 | Resin wheel | 12 | 130 | 180 | 1.5 | Mechanical |

| No.4 | 10S40 wheel | 60 | 130 | --- | 1.5 | Mechanical |

| No.5 | Resin wheel | 12 | 130 | 180 | 1.5 | Mechanical |

| No.6 | 10S40 wheel | 60 | 130 | --- | 1.5 | Mechanical |

| No. 7 | Resin wheel | 12 | 150 | 320 | 2.2 | Mechanical |

| No.8 | 10S40 wheel | 70 | 150 | --- | 2.2 | Mechanical |

| No.9 | felt wheel | 70 | 150 | --- | 1.5 | Mechanical |