Introduction

XQL-SB180 Automatic channel letter bending machine or channel letter bender mainly used for metallic signage of illuminated letter

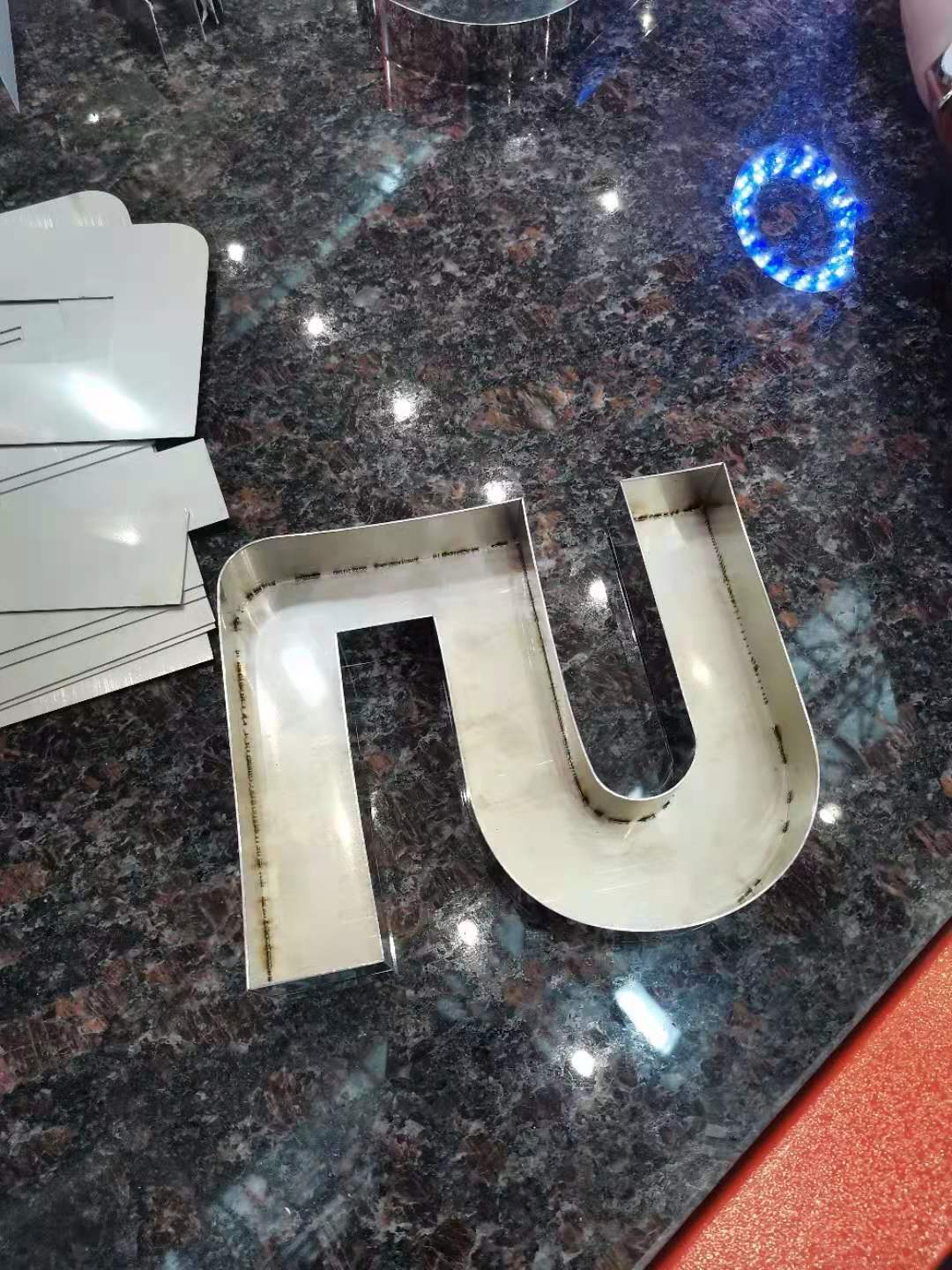

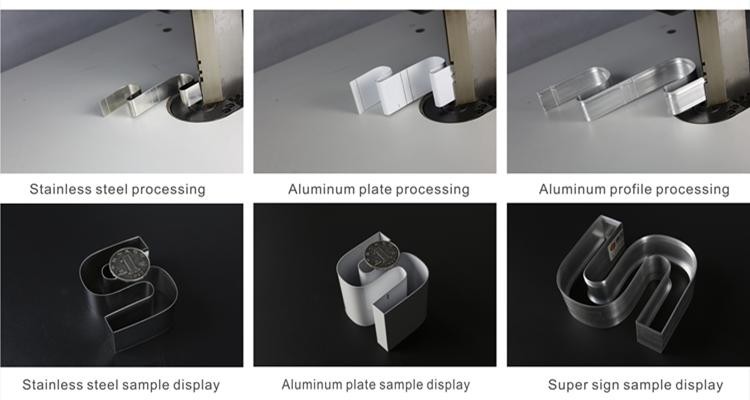

What you can make with a channel letter bending machine?

Samples

Please see our recent post for letter bending and letter welding machine installation in Sydney below:

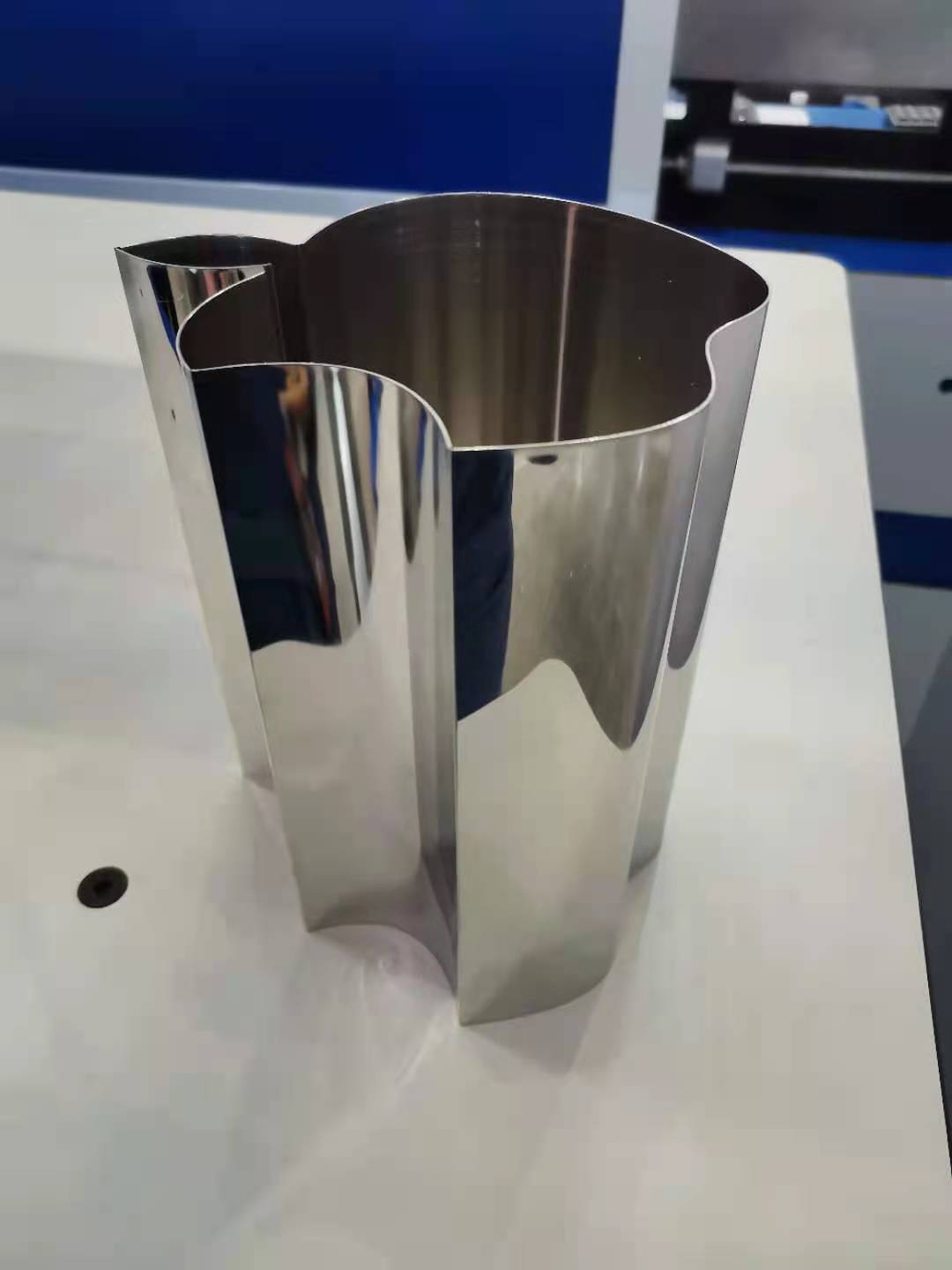

In the exhibition!

Some of our recent projects on letter bending machines described here and here

In this video you can see 200mm S letter made with SB-180 channel bending and machine parts overview, in an exhibition

About the manufacturer!

Manufacture introduction

Letter Bending Machine in action!

How does a channel bending machine work?

In brief, this machine works with special slotting tool and double blade alternating bending system. According to the graphics arc size and direction changes, automatically switches the corresponding bending blade. The blade reverses automatically to home, to avoid the bending blade interruption with finished corner, it is good at forming small arcs and angles.

Machine features:

The bend part control adopts servo motor, adjusted by a linear rail. Rigidity and torque of servo motor ,bending radius

and speed also, can be well controlled to ensure consistency with the duplicate files production and effectively avoids

the generation of surface marks. It can be a perfect match with laser, plasma machines or engraving machines.

Continuous roller feeding device

Rapid, sensitive and sustained response, short feeding time

Pressure settings for passive feed roller adjustment ,leads to an outstanding performance for different thickness of the material and eliminate material indentation due to excessive pressure .

Relying length encoder and closed-loop control system eliminates material slippage .

File matching accuracy ± 0.1mm.

Specification

| Feeding system | Circulation-type clamp feeding device |

|---|---|

| Slotting system | Plane cutter and milling cutter slotting system |

| Bending system | Double blade alternating bending system |

| Suitable materials | Stainless steel Galvanized steel Aluminum |

| Material height | 20-200mm |

| Material thickness | SS & galvanized≤1.2mm Aluminum ≤1.5mm |

| Minimum bending angle | SS, Galvanized, plate aluminum : R6 |

| Precision | ±0.1mm |

| File format | .dxf (.plt has lower resolution,results less accurate letters) |

| Machine size | L1577xW703XH1543MM |

| Power | AC220V 50hz 2.4kw |

| Air supply | 0.6m3/Min |

| weight | 510kgs |

| Assemabled machine size | L2410xW800XH1470MM=2.83m3 |

glue dosage calculation software

During making super channel letter , the calculation of glue dosage is a tedious and time-consuming process. A13ESW built-in glue dosage calculation software, improves processing efficiency.

The industry unique software system.

Software system developed by the Software Engineering Tianjin Yuan, based on years of industry experience and customer feedback, and continuous improvement of the software for material handling and human-computer interaction.

Built-in closed loop detection and conventional plates data compensates the length and angle according to different materials elasticity and ductility , easily copes with daily processing. From the user’s point of view, it will be a easy to use, easy to understand, user-friendly software delivered to you.