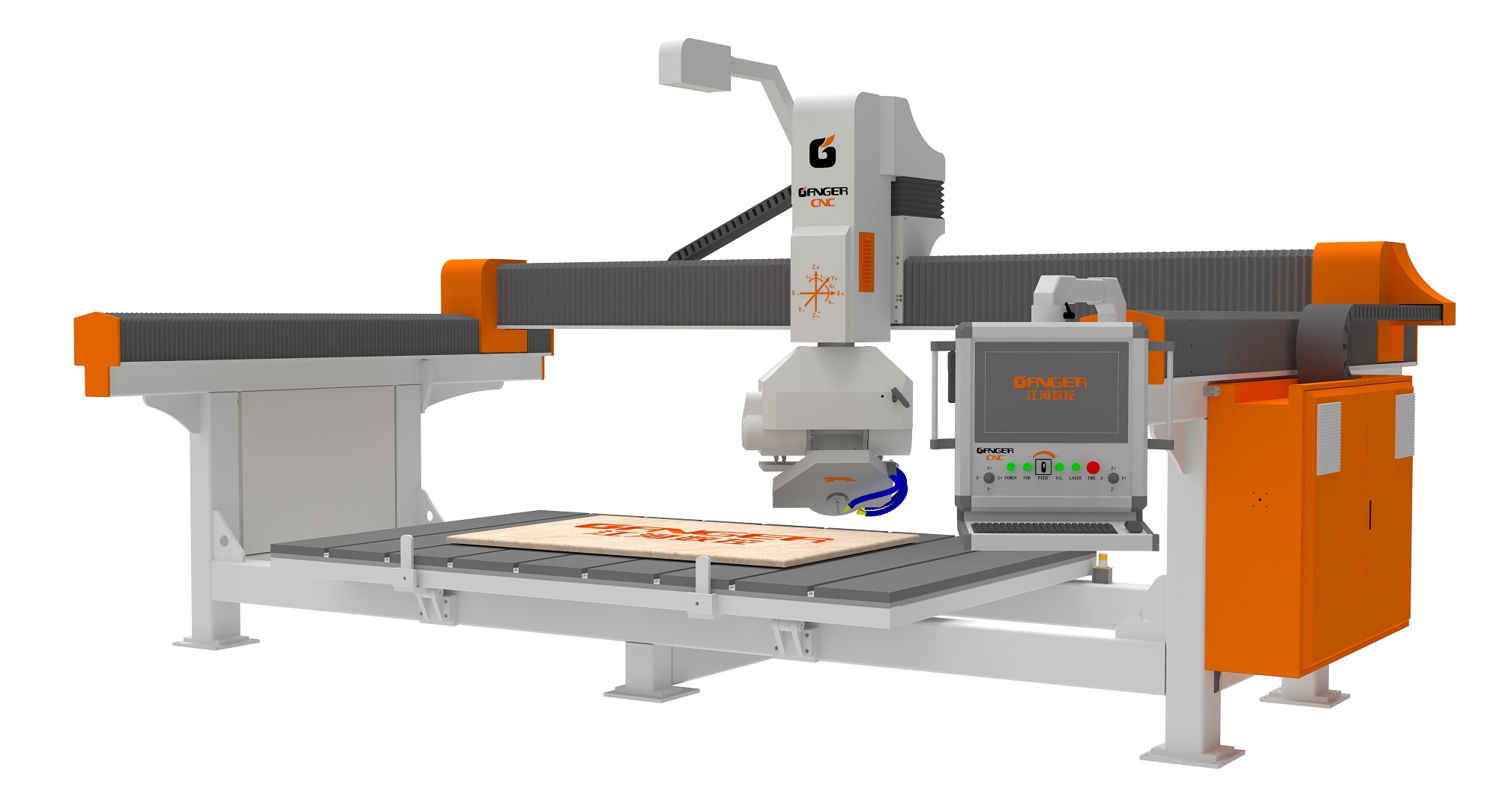

5 Axis Stone Bridge Cutting Machine GQ-3220DS

3220DS 5 Axis Bridge Saw features

3220DS 5 Axis Bridge Saw is a 15KW, camera equipped, with suction movement and Taiwan DELTA servo motors, for high precision and speed cutting of kitchen cabinets, counter-tops and decorative stones.

The main benefits of a 5 axis bridge saw are significant. Here are the key advantages:

- Enhanced Precision and Accuracy:

- The 5-axis capability allows for precise cutting and shaping of stone materials. It can cut complex shapes and designs with high accuracy, which is crucial for detailed and intricate stonework.

- Increased Versatility:

- With the ability to move in five different axes, these saws can create a wide range of cuts and shapes that are not possible with traditional 3-axis machines. This includes curves, bevels, and intricate patterns, making it highly versatile for various projects.

- Improved Efficiency and Productivity:

- The advanced automation and programming capabilities reduce the need for manual intervention, speeding up the cutting process. This leads to faster turnaround times and the ability to handle larger volumes of work.

- Cost Savings:

- Despite the higher initial investment, the efficiency and precision of a 5-axis bridge saw can lead to significant cost savings in the long run. Reduced material wastage, lower labor costs, and faster project completion contribute to overall cost-effectiveness.

- Better Material Utilization:

- The precise cutting ability ensures minimal wastage of expensive stone materials. This optimal material usage translates to cost savings and more sustainable operations.

- Enhanced Safety:

- Automation reduces the need for manual handling of heavy and potentially dangerous stone materials. This minimizes the risk of accidents and injuries in the workplace.

- Consistent Quality:

- The repeatability of automated cutting ensures consistent quality across multiple pieces. This is particularly important for large projects where uniformity is required.

- Reduced Labor Requirements:

- Automation reduces the need for highly skilled manual labor for cutting complex shapes. Operators can focus on programming and overseeing the machine, rather than performing the cutting manually.

- Advanced Software Integration:

- Many 5-axis stone bridge saws come with sophisticated software that allows for detailed planning and simulation before actual cutting. This helps in minimizing errors and optimizing the cutting process.

- Adaptability to Different Materials:

- These saws are not limited to a specific type of stone; they can cut various materials like granite, marble, and engineered stone with equal precision and efficiency.

By leveraging these benefits, stone fabrication businesses can enhance their capabilities, offer more complex and high-quality products, and remain competitive in a demanding market.

GQ-3220DS 5 axis bridge saw photos

GQ-3220DS with camera and suction movement

Programming with DXF file import on GQ-3220DS

Countertop cutout with hole saw drill bit and a saw blade(CAM & Simulation)

Programming with camera

Move axes manually

Another programming sample

Functions of 3220DS 5 axis bridge saw

- Cutting straight line, regular and irregular polygons, circle, oval, arc, hexagon, grid point and customized shapes.

- Nesting function

- 4 sides bevel/Miter cutting,

- drilling faucet holes, cutting sink hole, profiling and polishing inside edges of cutouts and outside edges of countertop,

- Contouring/Milling,

- Suction moving(both Manual and Automatic modes)

- Taiwan intelligent CNC control system, simple and intuitive. Quick programming on the controller, or input .NC and .DXF file by flash memory available.

- With double vacuum suction pad for pick up and move stone slabs automatically and manual mode.

- By infrared ray to confirm the position.

- C axis automatic rotation 0-360 degree, by servo motor and matched servo driver.

- A axis automatic tilting 0-90 degree, by servo motor and matched servo driver.

- Table tilting 0-85 degree, for load & unload materials easily.

- Working table upgraded to PVC (thickness 35mm) replace timber, high hardness, corrosion resistance, long service life.

- Monoblock stable structure, high precision, no edge chipping.

- Monoblock delivery, shipped 98% assembled, convenient installation.

Vertical cut

Horizontal cut

Unsquared cut

Diamond cut

Miter 45 Degree

Circle

Shaped cut

Drilling

Milling

Edge Polishing

Applicable industry & material

Applicable industry:

sintered stone application industry, fabricated building materials industry, home decoration materials industry, cutting marble, artificial stone, quartz stone and other materials.

Applicable materials:

sintered stone, ceramic plate, quartz stone, marble, etc.

Simple and economic stone bridge saw described here

Here is the manufacturer webpage and descriptions.

| 1 | Model No. | GQ-3220D |

|---|---|---|

| 2 | X/Y/Z Axis working size | X=3200mm, Y=2000mm, Z=500mm |

| 3 | Working table size | 3200mm x 2000mm |

| 4 | C axis rotation angle | 0°- 360° |

| 5 | A axis rotation angle | 0°– 90° |

| 6 | Blade motor power | 15KW(≈20.4HP) |

| 7 | Rotation speed of blade/saw | 3000rpm - 6000rpm (variable speed) |

| 8 | Variable Frequency Drive/Inverter | (VFD), 15KW(≈20.4HP) |

| 9 | Diameter of blade/saw | 350mm(≈13.78”) |

| 10 | Hydraulic Table tilting | 0°- 85° |

| 11 | Working table material | Good quality hard PVC |

| 12 | Control system | Taiwan CNC Control System (English, Chinese and Spanish versions) |

| 13 | Compatible software & file format | .DXF, .NC format, USB interface. |

| 14 | X, Y, Z Axis transmission | X/Y Helical rack and pinion, Z axis Taiwan Ball screw |

| 15 | Guide rail | Taiwan linear guide rail, X & Y 30mm, Z axis 25mm. |

| 16 | Drive motor | Servo motor with matching servo driver (6 SETS), in which the AC Servo motor(1.3KW) for Z axis with brake |

| 17 | Working voltage | 380V, 50HZ/60HZ, 3 phase |

| 18 | Automatic Lubricating system | With |

| 19 | Hydraulic System | With |

| 20 | Total power | 29KW |

| 21 | Water consumption | 4m3/h |

| 22 | Structure | Heavy duty bed and steady structure, monoblock design. |

| 23 | Gross weight | 4500KGS |

| 24 | Machine outside dimensions | 5700mm(Length)*3300mm(Width)*2950mm(Height) |

| 25 | Packing size | 98% assembled when delivery, easy to install when received. 5700mm*2250mm*2230mm(dismantle the steel cover of head, and the motor of Z axis, to be loaded into 20GP container). 5700mm*2250mm*2580mm(with all Z axis installed, no dismantled any parts of head, it can be loaded into 40HQ container). |

| 26 | Application | for cutting Dekton, marble, granite, porcelain tile, ceramic plate, quartz stone, silestone, artificial stone, etc. |