In this post I’m going to show you supply and install of CNC length stopper or digital stop for saw automation purposes.

CNC length stopper background

The similar machines in the market are Tiger stop and Profistop. It’s also known as CNC digital ruler and CNC size stopper.

Project

Friend of mine, had an Australian length stop at his factory in Ingleside, Sydney.

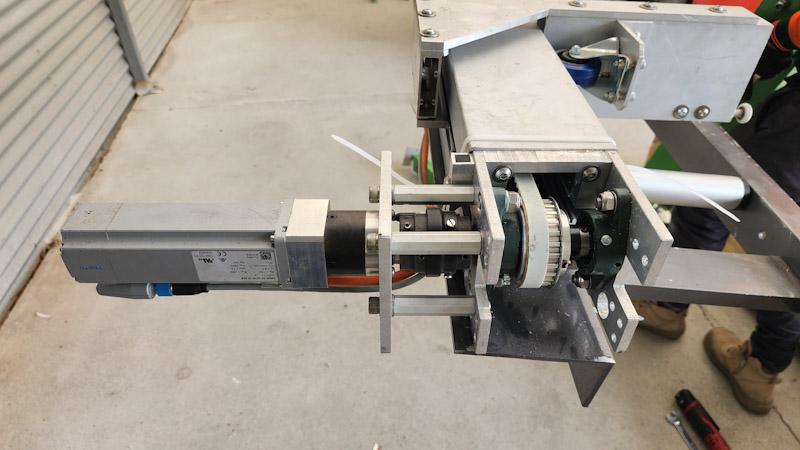

The main issue in this machine was the inaccurate length of the cut, because of weak linear motion structure. It had an aluminium profile and roller for stopper positioning with timing belt and after a couple of years of work, got loose.

The main suggestion was to replace the long timing belt with rack and pinion and take advantage of steel welded structure and linear blocks for increasing the positioning accuracy.

New machine

The above shown machine sourced from China, from an experienced manufacturer in this field.

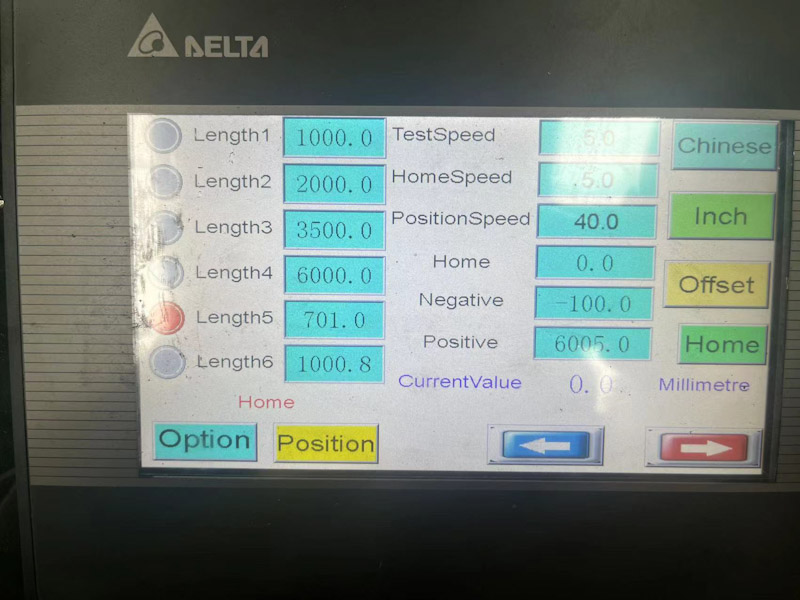

This machine takes advantage of a touch HMI screen and PLC to control the servo system for positioning.

We have another page about CNC controller installation here

Machine overview before shipment from the factory shown in the following video,

In the following video, machine operation training explained.

In the following video the machine’s operation in the factory before packing for shipment illustrated.

Suggestion for improvement

The stopper structure and robustness is good and we suggest to put both linear rails on the back side and cover them with an aluminium profile. This profile would be as a guide for raw material placement and protects linear motion parts from unwanted dust and contamination, too.

The servo motor has been installed horizontally in this design, which results in too much space taken at the back of the machine. We suggest the servo gearbox to be installed vertically and save space at the machine back. It would be safer for the workplace and avoid unwanted accidents, too.