The Essential Role of Edge Bander Repair in Woodworking

Woodworking is an art form and an industry where precision and attention to detail are paramount. Edge bander machines are a crucial component of any woodworking workshop, used to give a polished and finished look to the edges of wooden panels. To maintain the quality, efficiency, and safety of woodworking operations, the repair and maintenance of edge bander machines are of utmost importance. Here, we explore the significance of edge bander machine repair in the woodworking industry.

- Enhanced Product Quality: Edge banding is a finishing touch that can make or break the overall quality of a wood product. Regular maintenance and repair of edge bander machines ensure that the edges are consistently and accurately finished, contributing to a higher-quality end product.

- Cost Savings: Neglecting necessary repairs can lead to larger and more expensive problems down the line. Timely repair and maintenance of edge bander machines can prevent costly breakdowns and extend the lifespan of these valuable assets.

- Increased Efficiency: Efficient woodworking operations are critical for meeting production schedules and maintaining a competitive edge. A well-maintained edge bander machine is less likely to experience downtime, allowing for a smoother workflow and increased productivity.

- Safety First: Safety should always be a top priority in woodworking workshops. Damaged or malfunctioning edge bander machines can pose serious safety risks to operators. Regular repair and maintenance ensure that these machines operate safely.

- Minimized Material Waste: Precise edge banding minimizes material waste by ensuring that the edges of panels are properly sealed and finished. Wastage due to rework or rejects is reduced when edge bander machines are in optimal working condition.

- Longevity of Equipment: Edge bander machines are a significant investment for woodworking businesses. Regular repairs and maintenance can extend the lifespan of these machines, thus increasing their return on investment.

- Environmental Responsibility: In an era where environmental concerns are paramount, the woodworking industry is under pressure to minimize waste and energy consumption. A well-maintained edge bander machine is more likely to operate efficiently, thereby reducing its environmental footprint.

- Reliable Performance: A woodworking business’s reputation often hinges on reliability. Customers trust businesses that consistently deliver high-quality products on time. Regular repairs ensure that edge bander machines perform consistently, preventing disruptions and maintaining customer confidence.

- Expertise Matters: Repair and maintenance of edge bander machines require specialized knowledge and skills. Relying on qualified technicians to handle repairs ensures that the job is done correctly, and any potential issues are addressed before they worsen.

- Future-Proofing Your Workshop: The woodworking industry is constantly evolving, with new techniques, materials, and customer demands emerging. Regular maintenance and repairs help keep edge bander machines up-to-date and capable of handling new challenges and opportunities.

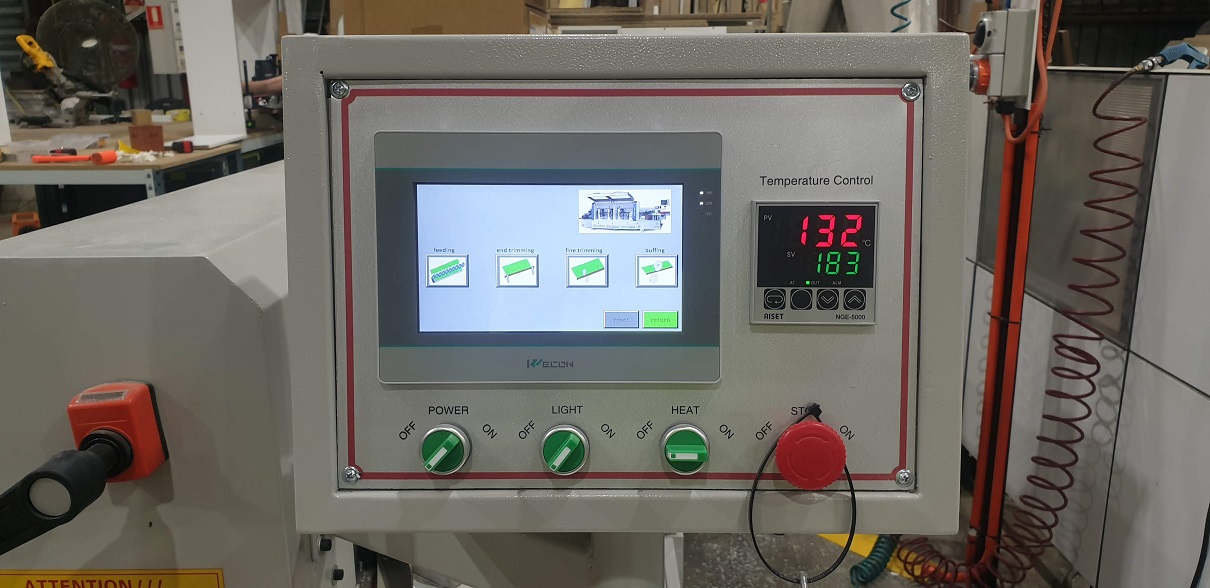

Edge banding repair process usually included glue pot check and maintenance to make sure enough glue applied to the edge, timing and various sensor control, pneumatic valves and actuators control and diagnostic, rough trimming wheels adjustment and scrapers fine tune.

Scraper plays an important role in final product quality and they would be checked in detail in any edge bander repair project.

What temperature should edge bander glue be?

Generally, edge bander machines use hot melt adhesives, and the ideal temperature range for these adhesives is typically between 180°C to 220°C. This temperature range allows the glue to be in a molten or semi-molten state, making it suitable for application to the edges of panels or boards.

In some edge bander repair cases maybe mechanical power transmission system has to be checked for faulty or broken parts.

Remember, the specific maintenance requirements can vary between different edge bander models and manufacturers, so always refer to the machine’s manual for guidelines tailored to your equipment. Regular and proactive maintenance can significantly contribute to the longevity and reliability of your edge banding machine.

You can contact us here for discussing your edge bander repair, when needed.

Some useful information about different edge machines described in this page

Tips and tricks

Please check this page for some tips and tricks for edge bander maintenance.

In conclusion, the importance of edge bander machine repair in the woodworking industry cannot be overstated. It is a fundamental aspect of ensuring product quality, safety, and efficiency. By investing in the regular upkeep of these machines, woodworking businesses can continue to produce high-quality products, save on costs, and maintain a competitive edge in a constantly changing market. Ultimately, the attention given to edge bander machine repair is a testament to a commitment to excellence and long-term success in the woodworking industry.