About Biesse Rover Plast B

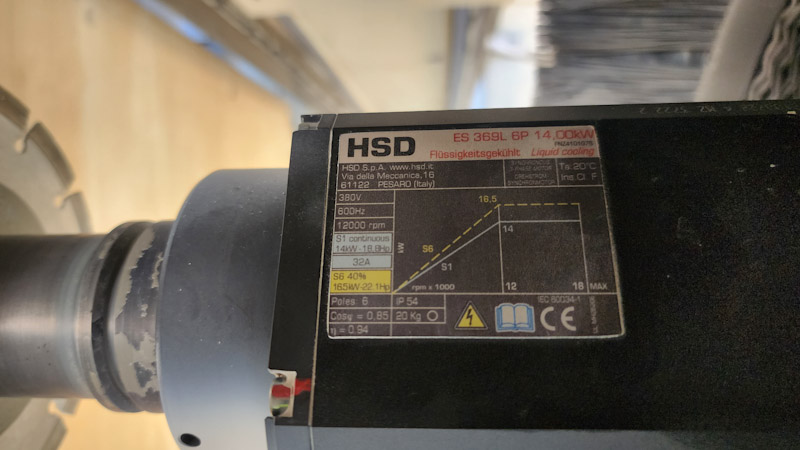

In this post we are going to show you HSD ES369L spindle repair. This project was for a 5 axis Rover Plast B, CNC machine from Biesse group.

HSD ES369L spindle seized after few years of work.

Very fine cement dust penetrated inside the bottom bearing and damaged bearings.

Similar projects

PDMach done some similar projects on spindle. Spindle repair project on INTERMAC MASTER 45 has been described in this page

Also, other projects on HSD spindle’s sensors in this page

Spindle removal

Spindle disconnected and removed for this spindle repair project.

14Kw synchronous spindle has been used on this machine to reach higher power with less weight at 12,000 rpm.

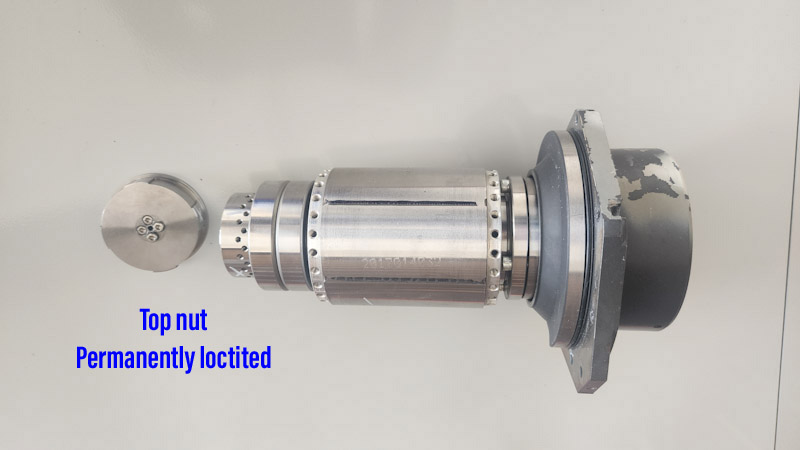

Spindle shaft easily removed by undoing the bottom socket M6 bolts.

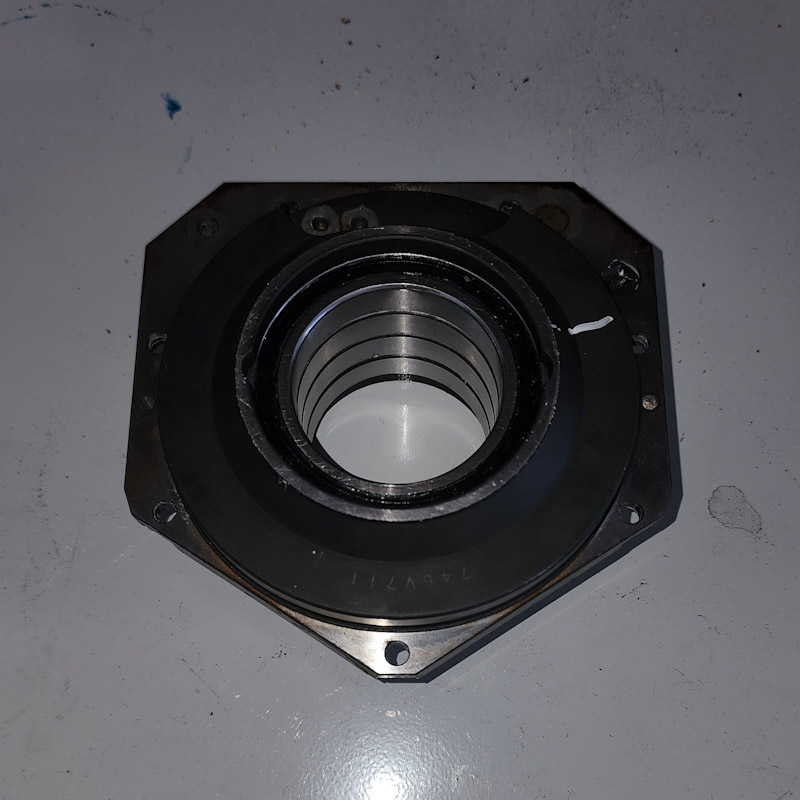

Here is the photo of this spindle’s stator.

An important note for removing the top special nut for removing 7007 bearings and rotor is heating up that nut up to 250C degrees, and opening while is still hot.

Bearing removal

Special tool with a flat bar by making four 3mm holes needed to open this nut.

For undoing the nut, at the same time needed to heat it up to 250C degrees and press spring clamp to free up the pressure.

As an alternative for hydraulic press, special tool can be made to pull down the tool clamp spring shaft and free up the top nut. For example 20mm threaded rod can be used by drilling and tapping it on the centre. This tool with M20 nut and washer will be used to pull the spring shaft down.

Please note that nut is left hand threaded.

For shaft removing is needed to undo a double nut. First four bolts just to be loosen and undo the nuts together.

Please note these nuts are left hand threaded, too.

Like the other parts, shaft is push fit in 50BNR19H bearings. In fact, no hyraulic press needed for this spindle bearings disassembly.

For removing 50BNR19H bearings, is needed to undo the above left hand threaded nut, with special flat bar tool designed and 3mm pins.

Bearing arrangement

As shown in the above picture, the arrangement is DBB according to NSK specifications.

HSD ES369L Spindle bearings

NSK super precision bearings as a guide for every spindle repair project described in details here

Here is the bearings number and designations for HSD ES369L spindle repair.

7007CSN24 TRV1VDUCA12P3

7: Bearing type, Standard series

0: Dimension series, 10 series

07: Bore number

C: Contact angle, 15 degree

SN24: Material, ceramic ball

TR: Cage, Outer ring guided phenolic cage

V1V: seal, Non-contact rubber seal

DU: Arrangement, 2 row

CA12: Preload, Special measured (+) axial clearance

P3: Accuracy, special class

50BNR19H TXVIVSUELP3

50: Nominal bore diameter

BNR: Bearing type

19: NSKROBUST series, 19 series

H: Material, Bearing steel (SUJ2), Balls (Si3N4)

TX: Cage

V1V: seal, Non-contact rubber seal

SU: Arrangement, single row

EL: Extra load preload

P3: Accuracy, special class

Sometimes NSK precision bearings are not in stock or for any reason needed to look for alternative precision bearings for spindle repair. Specifications and designation of FAG precision bearings described here

FAG alternatives

NSK: 7007CSN24 TRV1VDUCA12P3 FAG: HCS7007C

NSK: 50BNR19H TXVIVSUELP3 FAG: HCS71910

Assembly

Bearing handling plays an important role in achieving the best results.

Basic idea in super precision bearing handling and mounting described here

For permanent lock of the top nut of these 7007 bearings, suggest to use loctite 263 on this spindle repair project.